Catalytic cracking of M-100 fuel oil: relationships between origin process parameters and conversion products

Abstract

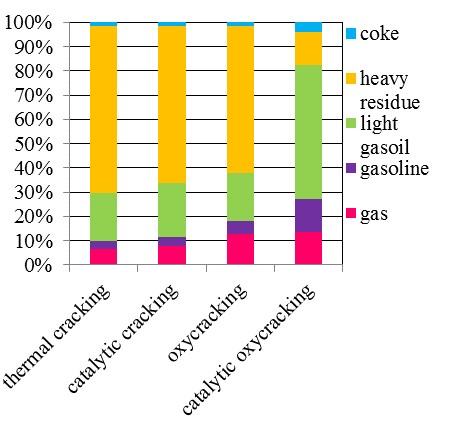

The development of technologies for processing oil residues is relevant and promising for Kazakhstan, since the main oil reserves of hydrocarbons in the country are in heavy oils. This paper describes the study of the influence of technological modes on the yield and hydrocarbon composition of products formed because of cracking of commercial fuel oil and fuel oil M-100 in the presence of air in the reactor. For catalysts preparation, natural Taizhuzgen zeolite and Narynkol clay were used. It was found that the introduction of air into the reaction zone, in which oxygen is the initiator of the cracking process, significantly increases the yield of the middle distillate fractions. In the presence of air, the yield of diene and cyclodiene hydrocarbons significantly increases compared to cracking in an inert atmosphere. According to the data of IR spectral analysis of M-100 grade oil fractions, in addition to normal alkanes, the final sample contains a significant amount of olefinic and aromatic hydrocarbons. On the optimal catalyst, owing to oxidative cracking of fuel oil, the following product compositions (in %) were established: Fuel oil M-100: gas – 0.8, gasoline – 1.1, light gas oil – 85.7, heavy residue – 11.9, loss – 0.5 and total – 100.0%; commodity Fuel oil (M-100): gas – 3.3, gasoline – 8.4, light gas oil – 84.3, heavy residue – 4.0, loss – 0 and total – 100.0%.

Keywords

Full Text:

PDFReferences

Pleshakova NA, Tyshchenko VA, Tomina NN, Pimerzin A. Hydrofining of oil fractions of naphthenoaromatic crude. Pet Chem. 2008;48(5):346–354. doi:10.1134/s0965544108050034

Yunusov MP, Djalаlova ShB, Nasullaev KhA, Gulyamov ShT, Isaeva NF, Mirzaeva EI. New catalytic systems for hydrofin-ing and dearomatization processes of oil fractions. Catal Sustain Energy. 2016;3:7–14. doi:10.1515/cse-2016-0003

Kerby MC, Degnan TF, Marler DO, Beck JS. Advanced cata-lyst technology and applications for high quality fuels and lubricants. Catal Today. 2005;104(1):55–063. doi:10.1016/j.cattod.2005.03.028

Gates BC, Ketzer JR, GCA Sehuit. Chemistry of Catalytic Processes. New York: Mcgraw-Hill; 1979. 464 p.

Erofeev VI, Adyaeva LV. Transformations of straight-run naphthas on indiummodified pentasils. Russ J Appl Chem. 2003;76:1083–1088. doi:10.1023/a:1026354210970

Omarova A, Sassykova L, Tulepov M, Zhakirova N. Study of non-hydrogen transformation of model n-alkanes and a diesel fraction over La-Zn-Mn/Al2O3+ZSM-catalyst. J Chem Technol Metall. 2019;54(3):547–554.

Prabhahar M, Sendilvelan S, Sassykova LR. Studies on pongamia oil methyl ester fueled direct injection diesel engine to reduce harmful emissions. Indian J Environ Prot. 2018;38(4):269–277.

Tuktin BT, Tenizbayeva AS, Omarova AA, Sassykova LR, Sailau ZhA. Hydrofining of petrol fractions of oil on modi-fied alumina catalysts. Rasayan J Chem. 2019;12(3):1478–1484. doi:10.31788/RJC.2019.1235236

Maryutina TA, Savonina EYu, Katasonova ON. A combined method of sample preparation for the determination of the total element composition of oils. J Anal Chem. 2016;71(11):1126–1130. doi:10.1134/s1061934816110101

Borzaev HH, Kolesnikov IM. Cracking of activated vacuum gas oil on mesoporous aluminosilicates. Oil and Gas Technol. 2020;128(3):9–12. doi:10.32935/1815-2600-2020-128-3-9-12

Rabeeah Taj, Erum Pervaiz, Arshad Hussain. Synthesis and catalytic activity of IM-5 zeolite as naphtha cracking catalyst for light olefins: a review. J Chem Soc Pak. 2020;42(2):305–316. doi:10.52568/000637/jcsp/42.02.2020

Shakiyeva TV, Sassykova LR, Khamlenko AA, Sassykova AR, Batyrbayeva AA, Zhaxibayeva ZhM, Kozhaisakova MA, Mu-ratova A, Dossumova BT, Abildin TS, Zhumagali M. Synthesis and testing catalysts based on fly ash from thermal power plants and natural zeolite for gas emissions purifica-tion and catalytic processing of heavy oil. Rasayan J Chem. 2021;14(4):2216–2223. doi:10.31788/RJC.2021.1446511

Ghashghaee M, Shirvani S, Kegnæs S. Steam catalytic cracking of fuel oil over a novel composite nanocatalyst: characterization, kinetics and comparative perspective. J Anal Appl Pyrolysis. 2019;138:281–293. doi:10.1016/j.jaap.2019.01.010

Ghashghaee M. Predictive correlations for thermal upgrading of petroleum residues. J Anal Appl Pyrolysis. 2015;115:326–336. doi:10.1016/j.jaap.2015.08.013

Tanimu A, Tanimu G, Alasiri H, Aitani A. Catalytic cracking of crude oil: mini review of catalyst formulations for enhanced selectivity to light olefins. Energy Fuels. 2022;36(10):5152–5166. doi:10.1021/acs.energyfuels.2c00567

Deng N, Liu T, He G, Wang Q. Optimization of waste paper’s catalytic cracking to liquid fuel using copper slag as the catalyst based on response surface methodology. J Anal Appl Pyrolysis. 2022;162:105463. doi:10.1016/j.jaap.2022.105463

Zhang Y, Alvarez-Majmutov A. Production of renewable liquid fuels by coprocessing HTL biocrude using hydrotreating and fluid catalytic cracking. Energy Fuels. 2021;35(23):19535–19542. doi:10.1021/acs.energyfuels.1c03152

Hwang K-R, Choi S-A, Choi I-H, Lee K-H. Catalytic cracking of chlorinated heavy wax from pyrolysis of plastic wastes to low carbon-range fuels: catalyst effect on properties of liquid products and dechlorination. J Anal Appl Pyrolysis. 2021;155:105090. doi:10.1016/j.jaap.2021.105090

Vu XH, Armbruster U. Engineering of zeolite crystals for catalytic cracking of triglycerides to renewable hydrocarbon fuels and chemicals: a review. Biomass Convers. Biore-fin. 2021. doi:10.1007/s13399-021-01389-x

Qiu B, Yang Ch, Shao Q, Liu Y, Chu H. Recent advances on industrial solid waste catalysts for improving the quality of bio-oil from biomass catalytic cracking: a review. Fuel. 2022;315:123218. doi:10.1016/j.fuel.2022.123218

Shakiyeva TV, Dossumova BT, Sassykova LR, Zhakirova NB. Study of the activating effect of introducing air additives into the reactor during fuel oil cracking on composite catalysts. Int J Mech Prod Eng Res Dev. 2020;10(3):4765–4776. doi:10.24247/ijmperdjun2020451

Maxwell IE, Stork WHJ. Chapter 17 Hydrocarbon processing with zeolites. Stud Surf Sci Catal. 2001;137:747–819. doi:10.1016/s0167-2991(01)80259-7

Zakumbaeva GD, Shapovalova LB, Tuktin BT, Omarova AA. Transformations of tetradecane on La/Al2O3+ZSM catalysts. Pet Chem. 2010;50:135–140. doi:10.1134/s096554411002009x

Belov GP, Matkovsky PE. Processes for the production of higher linear α-olefins. Pet Chem. 2010;50(4):283–289. doi:10.1134/s0965544110040055

Glagoleva OF, Kapustin VM. Improving the efficiency of oil treating and refining processes (review). Pet Chem. 2020;60(11): 1207–1215. doi:10.1134/s0965544120110092

Kapustin V, Chernysheva E, Maximova A, Zinchenko Yu. Development of new catalytic processes for processing petroleum feedstock. Pure Appl Chem. 2017;89(10):1579–1585. doi:10.1515/pac-2016-1122

Abul-Hamayel MA. Effect of feedstocks on high-severity fluid catalytic cracking. Chem Eng Technol. 2002;25(1):65–70. doi:10.1002/1521-4125(200201)25:1<65::aid-ceat65>3.0.co;2-p

Nilssona P, Massoth FE, Otterstedt J-E. Catalytic cracking of heavy vacuum gas oil. Appl Catal. 1986;26:175–189. doi:10.1016/s0166-9834(00)82550-6

Lee KH, Lee YW, Ha BH. Catalytic cracking of vacuum gas oil on the dealuminated mordenites. J Catal. 1998;178(1):328–337. doi:10.1006/jcat.1998.2171

Yemelyanova VS, Dossumova BT, Shakiyeva TV, Sassykova LR, Sendilvelan S. Modified aluminosilicate catalysts based on cenospheres of power plants for processing fuel oil into light fractions. Int J Mech Prod Eng Res Dev. 2019;9(4):1079–1086. doi:10.24247/ijmperdaug2019111

Shakiyeva TV, Sassykova LR, Khamlenko AA, Dossumova BT, Sassykova AR, Batyrbayeva AA, Zhaxibayeva ZhM, Ko-zhaisakova MA, Azhigulova RN, Sendilvelan S. Composite catalysts based on fly ash of thermal power plants and natural zeolite for purification of gas emissions and catalytic cracking of fuel oil. ARPN J Eng Appl Sci. 2021;16(18):1877–1885.

Dadyburjor DB, Liu ZY. Selectivity and yield of components of a composite cracking catalyst: effect of interactions between composite components. J Catal. 1993;141(1):148–160. doi:10.1006/jcat.1993.1126

Talman JA, Reh L. An experimental study of fluid catalytic cracking in a downer reactor. Chem Eng J. 2001;84(3):517–523. doi:10.1016/s1385-8947(00)00375-2

Gong J. Study on preparation of fuel oil from three kinds of molecular sieve catalytic cracking waste lubricating oil. J Phys Conf Ser. 2022;2168:012010. doi:10.1088/1742-6596/2168/1/012010

Mani M, Thangavelu Th, Perumal SKr, Kannan Sh. Development and experimental validation of reactor kinetic model for catalytic cracking of eugenol, a potential bio additive fuel blend. Int J Chem React Eng. 2021;19(10):1023–1030. doi:10.1515/ijcre-2021-0059

Almutalabi ShN, Alzuhairi M, Hashim FA. Two stages thermal and catalytic cracking of polyethylene terephthalate to fuel production. Int J Des Nat Ecodyn. 2021;16(6):725–732. doi:10.18280/ijdne.160615

Gomez N, Molina A. Analysis of the particle clustering phenomenon in the fluid catalytic cracking of gasoil in a downer reactor. Chem Eng Technol. 2019;42(6):1293–1303. doi:10.1002/ceat.201800463

Fukase S, Maruyama F. Catalytic cracking of VGOs derived from hydroprecessing (Part 1). J Japan Pet Inst. 1994;37(6):611–619. doi:10.1627/jpi1958.37.611

Standl S, Hinrichsen O. Kinetic modeling of catalytic olefin cracking and methanol-to-olefins (MTO) over zeolites: a review. Catalysts. 2018;8(12):626. doi:10.3390/catal8120626

Beltramini JN. Catalytic properties of heteropolyacids supported on MCM-41 mesoporous silica for hydrocarbon cracking reactions. Stud Surf Sci Catal. 2003;146:653–656.

Pasl A Jalil, Mohammed A Al-Daous, Abdul-Rahman A Al-Arfaj, Adnan M Al-Amer, Jorg Beltramini, Sami AI Barri. Characterization of tungstophosphoric acid supported on MCM-41 mesoporous silica using n-hexane cracking, ben-zene adsorption, and X-ray diffraction. Appl Catal A-Gen. 2001;207(1–2):159–171. doi:10.1016/s0926-860x(00)00670-0

Kim SW, Yeo CE, Lee DY. Effect of fines content on fluidity of FCC catalysts for stable operation of fluid catalytic cracking unit. Energies. 2019;12(2):293. doi:10.3390/en12020293

Kolesnikov SI, Zvyagin VO, Kolesnikov IM. Catalytic cracking and reforming in the presence of atmospheric oxygen. Chem Tech Fuels Oils. 1999;35(2):57–60. doi:10.1007/bf02694144

Zvyagin VO, Matveeva NK, Samokhvalov AI, Tselidi EI. Cat-alytic cracking of vacuum distillate in the presence of oxygen. Chem Tech Fuels Oils. 1990;26(12):617–619. doi:10.1007/bf00727752

Ho TC. Hydroprocessing catalysis on metal sulfides prepared from molecular complexes. Catal Today. 2008;130(1):206–220. doi:10.1016/j.cattod.2007.06.076

Senter C, Mastry MC, Mannion AM, McGuire Jr R. Quantita-tive visual characterization of contaminant metals and their mobility in fluid catalytic cracking catalysts. Catalysts. 2019;9(10):831. doi:10.3390/catal9100831

Okunev AG, Parkhomchuk EV, Lysikov AI, Parunin PD, Se-meikina VS, Parmon VN. Catalytic hydroprocessing of heavy oil feedstocks. Russ Chem Rev. 2015;9:987–999. doi:10.1070/rcr4486

Ortega García FJ, Juárez EJ. Heavy oil hydrocracking on a liquid catalyst. Energy Fuels. 2017;31(8):7995–8000. doi:10.1021/acs.energyfuels.7b01132

Marafi M, Furimsky E. Hydroprocessing catalysts containing noble metals: deactivation, regeneration, metals reclamation, and environment and safety. Energy Fuels. 2017;31(6):5711−5750. doi:10.1021/acs.energyfuels.7b00471

Nwankwor PE, Onuigbo IO, Chukwuneke CE, Yahaya MF, Agboola BO, Jahng WJ. Synthesis of gasoline range fuels by the catalytic cracking of waste plastics using titanium dioxide and zeolite. Int J Energy Environ Eng. 2021;12:77–86. doi:10.1007/s40095-020-00359-9

Abedeen A, Hossain MdSh, Som U, Moniruzzaman MD. Catalytic cracking of scrap tire-generated fuel oil from pyrolysis of waste tires with zeolite ZSM-5. Int J Sustain Eng. 2021;14(6):2025–2040. doi:10.1080/19397038.2021.1951883

Diao Zh, Rong D, Hou X, Chen Y, Zheng P, Liu Y, Sun D. Catalytic cracking of endothermic fuels over meso-HZSM-5/MCM-41 coatings. Energy Fuels. 2019;33(12):12696–12703. doi:10.1021/acs.energyfuels.9b03458

Hamdan M, Halawy L, Aramouni NAK, Ahmad MN, Zeaiter J. Analytical review of the catalytic cracking of methane. Fuel. 2022;A324:124455. doi:10.1016/j.fuel.2022.124455

https://en.wikipedia.org/wiki/Fuel_oil

http://rostatneft.com/fuel/fuel-oil-m-100-2.html

Ajinomokh KSh. Physicochemical methods of activation of components of heavy petroleum raw materials [dissertation]. Moscow (Russia): MIREA — Russian Technological University; 2005. 206 p.

Pivovarova NA. Use of wave effect in processing of the hydrocarbonic raw material (Review). Pet Chem. 2019;59(6):559–569. doi:10.1134/s002824211907013x

Shakiyeva TV, Sassykova LR, Dzhatkambayeva UN, Zhakirova NK, Prabhahar M, Sendilvelan S, Ganesan M, N Jaya Chitra, Rajeswari Hari. Studying the regularities of oxida-tive catalytic cracking of vacuum distillates. Mater Today Proc. 2021;45(7):6028–6034. doi:10.1016/j.matpr.2020.09.642

Shakiyeva TV, Sassykova LR, Dzhatkambayeva UN, Kham-lenko AA, Zhakirova NK, Batyrbayeva AA, Azhigulova RN, Kubekova ShN, Zhaxibayeva ZhM, Kozhaisakova MA, Zhusupova LA, Sendilvelan S, Bhaskar K. Optimization of the oxidative cracking of fuel oil on catalysts obtained from Kazakhstan raw materials. Rasayan J Chem. 2021;14(2):1056–1071. doi:10.31788/RJC.2021.1426152

Musina NS, Maryutina TA. Application of magnetic treatment to changing the composition and physicochemical properties of crude oil and petroleum products. J Anal Chem. 2016;71(1):27–34. doi:10.1134/s1061934816010081

Likhterova NM, Lunin VV. Nontraditional methods for pro-cessing heavy petroleum feedstocks. Chem Tech Fuels Oils. 1998;34(6):325–329. doi:10.1007/bf02694114

Baradaran S, Sadeghi MT. Desulfurization of non-hydrotreated kerosene using hydrodynamic cavitation as-sisted oxidative desulfurization (HCAOD) process. J Environ Chem Eng. 2020;8(4):103832. doi:10.1016/j.jece.2020.103832

Zhakirova NK, Salakhov RKh, Sassykova LR, Khamidullin RF, Deberdeev TR, Yalyshev UR, Khamidi AR, Seilkhanov TM. Increasing the yield of light distillates by wave action on oil raw materials. Eurasian Chem-Technol J. 2021;23(2):125–132. doi:10.18321/ectj1083

Byshov NV, Simdyankin AA, Uspensky IA, Pukov RV. Ac-counting for the time of ultrasonic fuel processing in the surface tension coefficient. ARPN J Eng Appl Sci. 2019;14(21):3753–3756.

Khamidullin RF, Kharlampidi KhE, Nikulin RM, Sitalo AV, Sharaf FA. Increasing the yield of light distillates by activation of oil stock. Chem Technol Fuels Oils. 2017;52(6):670–678. doi:10.1007/s10553-017-0759-9

https://www.oil-industry.net/Journal/archive_detail.php?art=115139

https://en.everybodywiki.com/Dubrovay_Carl

Keynejad K, Nikazar M, Dabir B. Diesel desulfurization using a ultrasound-assisted oxidative process. Pet Sci Technol. 2018;36(11):718–725. doi:10.1080/10916466.2018.1445099

Sviridenko NN, Golovko AK. The effect of pre-ozonation of natural bitumen on the rate of cracking reactions. J Sib Fed Univ: Chem. 2020;13(1):78–88. doi:10.17516/1998-2836-0163

Hong PKA, Cha Z, inventors; University of Utah Research Foundation, assignee. Ozonation conversion of heavy hy-drocarbons for resource recovery. United States patent US20130292297 A1. 2013 Nov 7.

Zaykin YA, Zaykina RF. Stimulation of radiation-thermal cracking of oil products by reactive ozone-containing mixtures. Radiat Phys Chem. 2004;71(1–2):475–478. doi:10.1016/j.radphyschem.2004.04.075

Likhterova NM, Lunin VV, Torkhovskii VN, Fionov AV, Kollin A. Transformations of the components of heavy petroleum feedstock by ozone. Chem Tech Fuels Oils. 2004;40(4):248−255. doi:10.1023/b:cafo.0000041223.91179.af

Liu X, Li W, Xu H, Chen Y. A comparative study of non-oxidative pyrolysis and oxidative cracking of cyclohexane to light alkenes. Fuel Process Technol. 2004;86(2):151–167. doi:10.1016/j.fuproc.2004.01.002

Hubesch R, Mazur M, Selvakannan PR, Föger K, Lee AF, Wil-son K, Bhargava S. Endothermic catalytic cracking of liquid hydrocarbons for thermal management of high-speed flight vehicles. Sustain Energy Fuels. 2022;6(7):1664–1686. doi:10.1039/D1SE01999F

Thangadurai T, Tye ChTh. Acidity and basicity of metal oxide-based catalysts in catalytic cracking of vegetable oil. Braz J Chem Eng. 2021;38:1–20. doi:10.1007/s43153-020-00085-z

DOI: https://doi.org/10.15826/chimtech.2022.9.3.01

Copyright (c) 2022 Tatyana V. Shakiyeva, Larissa R. Sassykova, Anastassiya A. Khamlenko, Ulzhan N. Dzhatkambayeva, Albina R. Sassykova, Aigul A. Batyrbayeva, Zhanar M. Zhaxibayeva, Akmaral G. Ismailova, Subramanian Sendilvelan

This work is licensed under a Creative Commons Attribution 4.0 International License.

Chimica Techno Acta, 2014–2025

eISSN 2411-1414

Copyright Notice