Activity features of catalysts for thermocatalytic hydrogenation processing of polymer waste

Abstract

Keywords

Full Text:

PDFReferences

Soares FA, Steinbüchel A. Natural rubber degradation products: Fine chemicals and reuse of rubber waste. Eur Polym J. 2022;165:111001. doi:10.1016/j.eurpolymj.2022.111001

Datta J, Kopczyńska P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit Rev Environ Sci. 2016;46(10):905–946. doi:10.1177/00952443221087351

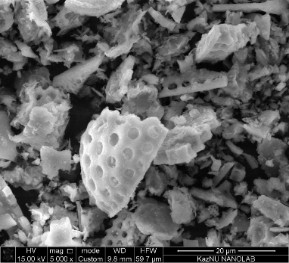

Dang TH, Nguyen XH, Chou ChL, Chen BH. Preparation of cancrinite-type zeolite from diatomaceous earth as transesterification catalysts for biodiesel production. Renew En-ergy. 2021;174:347–358. doi:10.1016/j.renene.2021.04.068

Song CS. An overview of new approaches to deep desulfurization for ultraclean gasoline, diesel fuel and jet fuel. Catal Today. 2003;86:211–263. doi:10.1016/S0920-5861(03)00412-7

Akesson D, Fuchs T, Stoss M, Root A, Stenvall E, Skrifvars M. Recycling of wood fiber-reinforced HDPE by multiple reprocessing. J Appl Polym Sci. 2016;133(35):43877. doi:10.1002/app.43877

Tashmukhambetova ZK, Aubakirov YA, Sassykova LR, Bur-khanbekov KE, Faizullaeva MF, Zhakirova NK. Non-conventional methods of preparation of polymer waste to catalytic processing into the fuel. Rev Roum Chim. 2018;63(11):1001–1009.

Hong Lim BK, Thain ES. Biodegradation of polymers in managing plastic waste. Sci Total Environ. 2022;813:151880. doi:10.1016/j.scitotenv.2021.151880

Kazemi M, Fini E. State of the art in the application of functionalized waste polymers in the built environment. Resour Conserv Recycl. 2022;177:105967. doi:10.1016/j.resconrec.2021.105967

Pradeep P, Gowthaman S. Extraction of transportation grade fuels from waste LDPE packaging polymers using catalytic pyrolysis. Fuel. 2022;323:124416. doi:10.1016/j.fuel.2022.124416

Chaturvedi AK, Pappu A, Gupta MK. Unraveling the role of agro waste-derived graphene quantum dots on dielectric and mechanical property of the fly ash based polymer nanocomposite. J Alloys Compd. 2022;903:163953. doi:10.1016/j.jallcom.2022.163953

Radeef HR, Hassan NA, Katman HY, Mahmud MZ, Abidin AR, Ismail CR. The mechanical response of dry-process polymer wastes modified asphalt under ageing and moisture damage. Case Stud Constr Mater. 2022;16:e00913. doi:10.1016/j.cscm.2022.e00913

Akin M, Polat R. The effect of vehicle waste tires on the mechanical, hardness and stress–strain properties of polyester-based polymer concretes. Constr Build Mater. 2022;325:126741. doi:10.1016/j.conbuildmat.2022.126741

Lopez M, Barrera G, Delgado R, Gencel O. Recycling poly-propylene and polyethylene wastes in production of polyester based polymer mortars. Constr Build Mater. 2021;274:121487. doi:10.1016/j.conbuildmat.2020.121487

Zhang W, Zhang J, Ding Y, Zhou R, Mao Sh. The accuracy of multiple methods for estimating the reaction order of representative thermoplastic polymers waste for energy utilization. Energy. 2022;239:122112. doi:10.1016/j.energy.2021.122112

Das O, Babu K, Shanmugam V, Sykam K, Tebyetekerwa M, Neisiany R, Forsth M, Sas G, Libreros J, Capezza A, Hedenqvist M, Berto F, Ramakrishna S. Natural and indus-trial wastes for sustainable and renewable polymer composites. Renew Sustain Energy Rev. 2022;158:112054. doi:10.1016/j.rser.2021.112054

Peng W, Wang Zh, Shu Y, Lu F, Zhang H, Shao L, He P. Fate of a biobased polymer via high-solid anaerobic co-digestion with food waste and following aerobic treatment: Insights on changes of polymer physicochemical properties and the role of microbial and fungal communities. Bioresour Tech-nol. 2022;343:126079. doi:10.1016/j.biortech.2021.126079.

Phakedi D, Ude A, Oladijo Ph. Co-pyrolysis of polymer waste and carbon-based matter as an alternative for waste management in the developing world. J Anal Appl Pyrolysis. 2021;155:105077. doi:10.1016/j.jaap.2021.105077

Jayamani E, Ki C, Rahman R, Bakri M. Recycled Plastic Bio-composites. Sawston: Woodhead Publishing; 2022. 81–96 p. doi:10.1016/B978-0-323-88653-6.00009-2

Lin H, Wang W, Kikhtyanin O, Kubicka D, Feng Zh, Guo Ch, Bai X, Xiao L, Wu W. Highly effective Pd/ZSM-12 bifunctional catalysts by in-situ glow discharge plasma reduction: the effect of metal function on the catalytic performance for n-hexadecane hydroisomerization. J Taiwan Inst Chem Eng. 2022;134:104303. doi:10.1016/j.jtice.2022.104303

Munyentwali A, Li H, Yang Q. Review of advances in bifunctional solid acid/base catalysts for sustainable biodiesel production. Appl Catal A Gen. 2022;633:118525. doi:10.1016/j.apcata.2022.118525

Shahi A, Roozbehani B, Mirdrikvand M. Catalytic pyrolysis of waste polyethylene terephthalate granules using a Lew-is-Brønsted acid sites catalyst. Clean Technol Environ Policy. 2022;24(3):779–787. doi:10.1007/s10098-021-02260-3

Duangdee B, Rattanaphra D, Nuchdang S, Thanapimmetha A, Saisriyoot M, Srinophakun P. Bifunctional mixed rare earth solid catalyst for biodiesel production from acid palm oil. J Rare Earths. 2022. doi:10.1016/j.jre.2022.02.007

Seliverstov ES, Furda LV, Lebedeva OE. Thermocatalytic conversion of plastics into liquid fuels over clays. Polym. 2022;14(10):2115. doi:10.3390/polym14102115

Qian T, Li J, Min X, Deng Y, Guan W, Ning L. Diatomite: A promising natural candidate as carrier material for low, middle and high temperature phase change material. Energy Convers Manag. 2015;98:34. doi:10.1016/j.enconman.2015.03.071

Usman MR, Munir D. Waste plastics to liquid fuels over Al-Impregnated zeolite beta catalyst. Int J Mater Sci Eng. 2020;8(2):32–37. doi:10.17706/ijmse.2020.8.2.32-37

Berkowicz-Platek G, Leski K, Zukowski W, Wrona J. Processing of low-density waste in fluidized bed made out of lightweight expanded clay aggregate. J Clean Prod. 2022;349:131328. doi:10.1016/j.jclepro.2022.131328

Yaashikaa P, Senthil P, Jeevanantham S, Saravanan R. A review on bioremediation approach for heavy metal detoxification and accumulation in plants. Environ Pollut. 2022;301:119035. doi:10.1016/j.envpol.2022.119035

Tashmukhambetova Zh, Aubakirov Y, Shomanova Zh, Burkhanbekov K, Safarov R, Sassykova L, Zhakirova N, Faizullaeva M. The effects of pretreatment methods of carbon-containing wastes in thermal catalytic recycling. Orient J Chem. 2017;33(6):2884–2890. doi:10.13005/ojc/330622

Aubakirov YA, Sassykova LR, Tashmukhambetova Zh Kh, Akhmetova FZh, Sendilvelan S, Sharipov KO, Kubekova ShN, Batyrbayeva AA, Azhigulova RN, Ryskaliyeva RG, Zhussupova AK, Abildin TS. Thermo-catalytic processing of polymer waste over catalysts on the basis of natural zeolite from the Tayzhuzgen field (Kazakhstan) modified by mo-lybdenum. Rasayan J Chem. 2019;12(4):1701. doi:10.31788/RJC.2019.1245435

Akhmetova F, Aubakirov Y, Tashmukhambetova Z, Sassyko-va L, Arbag H, Kurmangaliyeva A. Recycling of waste plastics to liquid fuel mixture over composite zeolites catalysts. Chem. Bull. Kaz. Nat. Univ. 2021; 2:12-18. doi:10.15328/cb1117

Shomanova Z, Safarov R., Tashmukhambetova Z, Sassykova L, Nosenko Y, Mukanova R. Complex research of ferroalloys production wastes by physical and chemical methods. J. Chem Technol Metall. 2021; 56(3):629–636.

Yang P, Kong F, Sui X, Zhao L, Qiu Y, Zhang H, Wang Zh. Hollow structured Zn0.76Co0.24S–Co9S8 composite with two-phase synergistic effect as bifunctional catalysts. Int J Hy-drog Energy. 2022;47(14):8811–8819. doi:10.1016/j.ijhydene.2021.12.238

Jakab-Nacsa A, Sikora E, Prekob A, Vanyorek L, Szori M, Boros R, Nehez K, Szabo M, Farkas L, Viskolcz B. Comparison of catalysts with MIRA21 model in heterogeneous catalytic hydrogenation of aromatic nitro compounds. Catalysts. 2022;12(5):467. doi:10.3390/catal12050467

Mironenko RM, Likholobov VA, Belskaya OB. Nanoglobular carbon and palladium–nanoglobular carbon catalysts for liquid-phase hydrogenation of organic compounds. Russ Chem Rev. 2022;91(1):RCR5017. doi:10.1070/RCR5017

Yan YT, Wu G, Chen SCh, Wang YZh. Controlled synthesis and closed-loop chemical recycling of biodegradable copolymers with composition-dependent properties. Sci China Chem. 2022;65:943–953. doi:10.1007/s11426-021-1196-7

Chaturvedi A, Pappu A, Gupta M. Unraveling the role of agro waste-derived graphene quantum dots on dielectric and mechanical property of the fly ash based polymer nanocomposite. J Alloys Compd. 2022;903:163953. doi:10.1070/RCR4940

Song D, Wang Y, Yip Ch-F, Zuo Q. Depolymerization for polymers with heteroatom-containing main chain: mechanism and applications. J Phys Conf Ser. 2022;2229:012008. doi:10.1088/1742-6596/2229/1/012008

Maafa IM. Biodiesel synthesis from high free-fatty-acid chicken fat using a scrap-tire derived solid acid catalyst and KOH. Polymers. 2022;14(3):643. doi:10.3390/polym14030643

Filippov SP, Yaroslavtsev AB. Hydrogen energy: development prospects and materials. Russ Chem Rev. 2021;90(6):627. doi:10.1070/RCR5014

Kustov L, Kustov A, Salmi T. Processing of lignocellulosic polymer wastes using microwave irradiation. Mendeleev Commun. 2022;32(1):1–8. doi:10.1016/j.mencom.2022.01.001

Amenaghawon A, Obahiagbon K, Isesele V, Usman F. Optimized biodiesel production from waste cooking oil using a functionalized bio-based heterogeneous catalyst. Clean Eng Technol. 2022;8:100501. doi:10.1016/j.clet.2022.100501

DOI: https://doi.org/10.15826/chimtech.2022.9.3.02

Copyright (c) 2022 Zheneta Kh. Tashmukhambetova, Tanakoz O. Kalamgali, Yermek A. Aubakirov, Larissa R. Sassykova, Firuza Zh. Akhmetova, Albina S. Alpysbay

This work is licensed under a Creative Commons Attribution 4.0 International License.

Chimica Techno Acta, 2014–2025

eISSN 2411-1414

Copyright Notice