Dilatometric characteristics of weakly sintered ceramics

Abstract

Keywords

Full Text:

PDFReferences

Zhu D, Miller RA. Development of Advanced Low Conductivity Thermal Barrier Coatings. Int J Appl Ceram Technol. 2004;1(1):86–94. doi:10.1111/j.1744-7402.2004.tb00158.x

Yang F, Zhao X, Xiao P. Thermal conductivities of YSZ/Al2O3 composites. J Eur Ceram Soc. 2010;30(15):3111–3116. doi:10.1016/j.jeurceramsoc.2010.07.007

Shen Z, He L, Xu Zh, Mu R, Huang G. Rare earth oxides stabilized La2Zr2O7 TBCs:EB-PVD, thermal conductivity and thermal cycling life. Surf. Coat. Technol. 2019;357:427–432. doi:10.1016/j.surfcoat.2018.10.045

Lyagaeva YG, Medvedev DA, Demin AK, Yaroslavtseva TV, Plaksin SV, Porotnikova NM. Specific features of preparation of dense ceramic based on barium zirconate. Semiconductors. 2014;48(10):1353–1358. doi:10.1134/S1063782614100182

Shahbazi H, Tataei M. A novel technique of gel-casting for producing dense ceramics of spinel (MgAl2O4). Ceram Int. 2019;45(A7):8727–8733. doi:10.1016/j.ceramint.2019.01.196

Lyagaeva YG, Medvedev DA, Demin AK, Tsiakaras P, Reznitskikh OG. Thermal expansion of materials in the barium cerate-zirconate system. Phys Solid State. 2015;7(2):285–289. doi:10.1134/S1063783415020250

Mohanraju S, Ramesha CM, Appaiah S, Kumar J, Krishna Prasad NJ. A study on the impact of coefficient of thermal expansion of Thermo-mechanical stresses on structural components. Mater Today Proc. 2021;46(7):2528–2533. doi:10.1016/j.matpr.2021.01.756

Mobasherpour I, Solati Hashjin M, Razavi Toosi SS, Darvishi Kamachali R. Effect of the addition ZrO2–Al2O3 on nanocrystalline hydroxyapatite bending strength and fracture toughness. Ceram Int. 2009;35(4):1569–1574. doi:10.1016/j.ceramint.2008.08.017

Yu QM, Cen L. Residual stress distribution along interfaces in thermal barrier coating system under thermal cycles. Ceram Int. 2017;43(3):3089–3100. doi:10.1016/j.ceramint.2016.11.119

Lim LY, Meguid SA. Thermomechanical simulations of the transient coupled effect of thermal cycling and oxidation on residual stresses in thermal barrier coatings. Ceram Int. 2022;48(3):3133–3147. doi:10.1016/j.ceramint.2021.10.087

Wei Z-Y, Cai H-N, Zhao S-D. Study on spalling mechanism of APS thermal barrier coatings considering surface vertical crack evolution affected by surrounding cracks. Ceram Int. 2022;48(8):11445–11455. doi:10.1016/j.ceramint.2022.01.001

Hutsaylyuk V, Student M, Zadorozhna Kh, Student O, Veselivska H, Gvosdetskii V, Maruschak P, Pokhmurska H. Improvement of wear resistance of aluminum alloy by HVOF method. J Mater Res Technol. 2020;9(6):16367–16377. doi:10.1016/j.jmrt.2020.11.102

Góral M, Swadźba R, Kubaszek T. TEM investigations of TGO formation during cyclic oxidation in two- and three-layered Thermal Barrier Coatings produced using LPPS, CVD and PS-PVD methods. Surf Coat Technol. 2020;394:125875. doi:10.1016/j.surfcoat.2020.125875

Ma D, Harvey TJ, Zhuk YN, Wellman RG, Wood RJK. Cavitation erosion performance of CVD W/WC coatings. Wear. 2020;452–453:203276. doi:10.1016/j.wear.2020.203276

Karaoglanli AC, Ozgurluk Y, Doleker KM. Comparison of microstructure and oxidation behavior of CoNiCrAlY coatings produced by APS, SSAPS, D-gun, HVOF and CGDS techniques. Vacuum. 2020;180:109609. doi:10.1016/j.vacuum.2020.109609

Grishina EP, Kudryakova NO, Ramenskaya LM. Thin-film Al2O3 coating on low carbon steel obtained by the sol–gel method with different peptizing acids: Corrosion investigation. Thin Solid Films. 2022;746:139125. doi:10.1016/j.tsf.2022.139125

Gallyamova R, Galyshev S, Musin F. Preparation of barrier SiO2 coating on carbon fibers by the sol-gel method. Mater Today Proc. 2019;11(1):286–289. doi:10.1016/j.matpr.2018.12.145

Deganello F, Tyagi AK. Solution combustion synthesis, energy and environment: Best parameters for better materials. Prog. Cryst. Growth Charact Mater. 2018;64(2):23–61. doi:10.1016/j.pcrysgrow.2018.03.001

Frikha K, Limousy L, Bouaziz J, Bennici S, Chaari K, Jeguirim M. Elaboration of alumina-based materials by solution combustion synthesis: A review. C. R. Chim. 2019;22(2–3):206–219. doi:10.1016/j.crci.2018.10.004

Lyagaeva J, Danilov N, Korona D, Farlenkov A, Medvedev D, Demin A, Animitsa I, Tsiakaras P. Improved ceramic and electrical properties of CaZrO3-based proton-conducting materials prepared by a new convenient combustion synthesis method. Ceram Int. 2017;43(9):7184–7192. doi:10.1016/j.ceramint.2017.03.006

Khaliullin ShM, Zhuravlev VD, and Bamburov VG. Solution-Combustion Synthesis of MZrO3 Zirconates (M = Ca, Sr, Ba) in Open Reactor: Thermodynamic Analysis and Experiment. Int J Self Propag High Temp Synth. 2017;26(2):93–101. doi:10.3103/S1061386217020078

Mukasyan AS, Costello C, Sherlock KP, Lafarga D, Varma A. Perovskite membranes by aqueous combustion synthesis: synthesis and properties. Sep Purif Technol. 2001;25(1–3):117–126. doi:10.1016/S1383-5866(01)00096-X

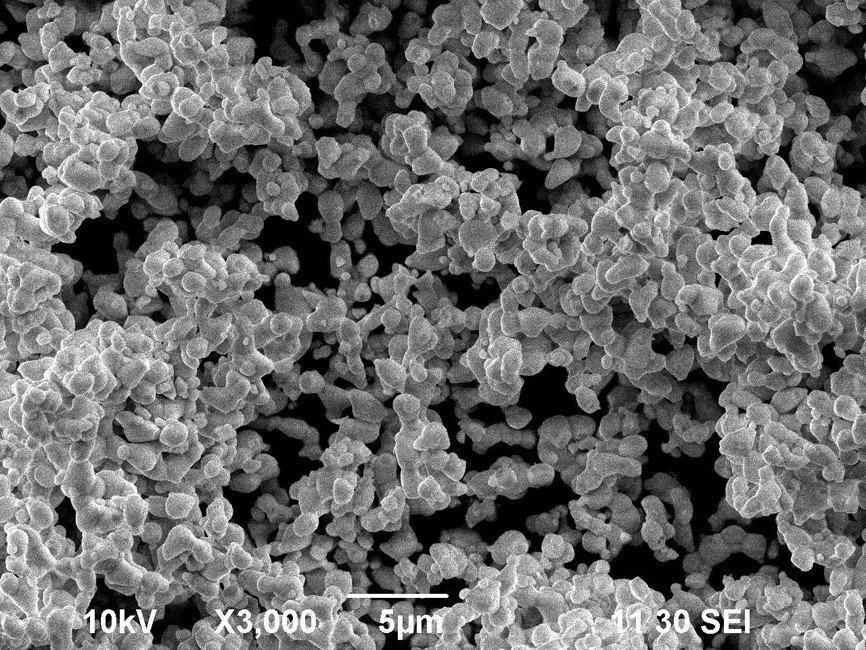

Zhuravlev V.D., Komolikov Yu.I., Ermakova L.V. Correlations among sintering temperature, shrinkage, and open porosity of 3.5YSZ/Al2O3 composites. Ceram Int. 2016;42:8005–8009. doi:10.1016/j.ceramint.2016.01.204

Rhodes WH. Agglomerate and particle size effects on sintering yttria-stabilised zirconia. J Am Ceram Soc. 1981;64(1):19–22. doi:10.1111/j.1151-2916.1981.tb09552.x

DOI: https://doi.org/10.15826/chimtech.2022.9.4.12

Copyright (c) 2022 Yury I. Komolikov, Larisa V. Ermakova, Vladimir R. Khrustov, Victor D. Zhuravlev

This work is licensed under a Creative Commons Attribution 4.0 International License.

Chimica Techno Acta, 2014–2025

eISSN 2411-1414

Copyright Notice