Structural transformations and their impact on the mechanical and antifriction properties in the process of alloying graphitized hypereutectoid steel with copper

Abstract

Keywords

Full Text:

PDFReferences

Osterle W, Prietzel C, Kloss, Dmitriev A. On the role of copper in brake friction materials. Tribol Int. 2010;43:2317–2326. doi:10.1016/j.triboint.2010.08.005

Agunsoye JO, Bello SA, Hassan SB, Adeymo RG, Odii JM. The effect of copper addition on the mechanical and wear properties of grey cast iron. J Minerals Mater Characteriz Engin. 2014;2(5):470–483. doi:10.4236/jmmce.2014.25048

Zhang B, Xu B, Xu Yi. Cu nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel-steel contacts. Tribol Int. 2011;44(7):878–886. doi:10.1016/j.triboint.2011.03.002

Zhai W, Lu W, Liu X. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol Int. 2019;129:75–81. doi:10.1016/j.triboint.2018.08.006

Rodrigues ACP, Oesterle W, Gradt T. Impact of copper nanoparticles on tribofilm formation determined by pin-on-disc tests with powder supply: Addition of artificial third body consisting of Fe3O4, Cu and graphite. Tribol Int. 2017;110:103–112. doi:10.1016/j.triboint.2017.02.014

Eroglu M. Boride coatings on steel using shielded metal ARC welding electrode: microstructure and hardness. Surface Coatings Technol. 2009;203:2229–2235. doi:10.1016/j.surfcoat.2009.02.010

Silman GI, Kamynin VV, Goncharov VV. On the mechanisms of copper effect on structure formation in cast iron. Metal Sci Heat Treatment. 2007;48(7–8):387–393. doi:10.1007/s11041-007-0072-z

May IL, Schetky LD. Copper in iron and steel. New York: Wiley Interscience; 1982. 423 p.

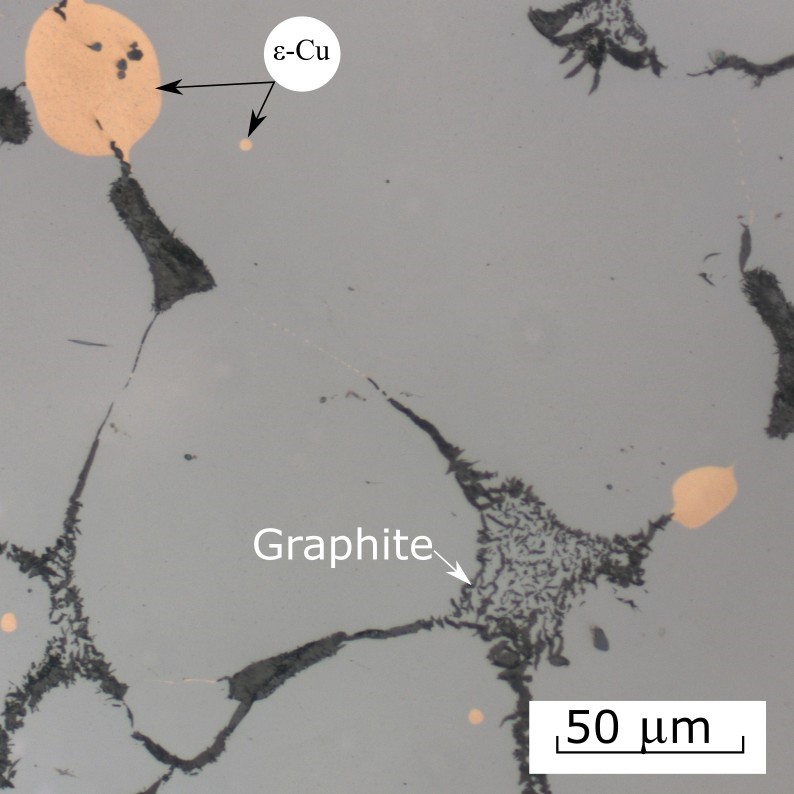

Bataev AA, Stepanova NV, Bataev IA, Kang Y, Razumakov AA. Special features of precipitation of ε-Cu phase in cast irons alloyed with copper and aluminum. Metal Sci Heat Treat. 2018;60(3–4):150–157. doi:10.1007/s11041-018-0253-y

Stepanova NV, Bataev IA, Kang Y, Lazurenko DV, Bataev AA, Razumakov AA, Jorge Junior AM. Composites of copper and cast iron fabricated via the liquid: In the vicinity of the limits of strength in a non-deformed condition. Mater Characteriz. 2017;130:260–269. doi:10.1016/j.matchar.2017.06.025

Upadhyay S, Saxena KK. Effect of Cu and Mo addition on mechanical properties and microstructure of grey cast iron: An overview. Mater Today Proc. 2020;26(2):2462–2470. doi:10.1016/j.matpr.2020.02.524

Sazegaran H, Teimoori F, Rastegarian H, Naserian-Nik AM. Effects of aluminum and copper on the graphite morphology, microstructure, and compressive properties of ductile iron. J Mining Metallurgy Sec B Metallurgy. 2021;57(1):145–154. doi:10.2298/JMMB191224006S

Garcia LN, Tolley AJ, Carazo FD, Boeri RE. Identification of Cu-rich precipitates in pearlitic spheroidal graphite cast irons. Mater Sci Technol. 2019;35(18):2252–2258. doi:10.1080/02670836.2019.1668999

Sil'man GI, Kamynin VV, Tarasov AA. Effect of copper on structure formation in cast iron. Metal Sci Heat Treat. 2003;45(7–8):254–258. doi:10.1023/A:1027320116132

Shubhank K, Kang Y. Critical evaluation and thermodynamic optimization of Fe–Cu, Cu–C, Fe–C binary systems and Fe–Cu–C ternary system. Calphad. 2014:45127–45137. doi:10.1016/j.calphad.2013.12.002

Sil’man GI. About retrograde solidus and stratification of melt in the Fe–Cu and Fe–Cu–C systems. Metal Sci Heat Treat. 2009;51(1–2):19–24. doi:10.1007/s11041-009-9120-1

Lazurenko DV, Alferova GI, Emurlaev KI, Emurlaeva YY, Bataev IA, Ogneva TS, Ruktuev AA, Stepanova NV, Bataev AA. Formation of wear-resistant copper-bearing layers on the surfaces of steel substrates by non-vacuum electron beam acladding using powder mixtures. Surface Coatings Technol. 2020;395:125927. doi:10.1016/j.surfcoat.2020.125927

Zhang GW, Kang YY, Wang MJ, Xu H, Jia HM. Atomic diffusion behavior and diffusion mechanism in Fe–Cu bimetal casting process studied by molecular dynamics simulation and experiment. Mater Res Express. 2020;7:096519. doi:10.1088/2053-1591/abb90f

Chen K, Chen X, Wang Z, Sandstrom HMR. Optimization of deformation properties in as-cast copper by microstructural engineering. Part I. Microstructure. J Alloys Compd. 2018:763:592–605. doi:10.1016/j.jallcom.2018.05.297

Buck DM. Copper in steel – the influence on corrosion. J Indust Engin Chem. 1913;5(6)447–452. doi:10.1021/ie50054a003

Li B, Qu H, Lang Y. Copper alloying content effect on pitting resistance of modified 00Cr20Ni18Mo6CuN super austenitic stainless steels. Corrosion Sci. 2020;173:108791. doi:10.1016/j.corsci.2020.108791

Sun XY, Zhang B, Wu B, Wei XX, Oguzie EE, Ma XL. Investigating the effect of Cu-rich phase on the corrosion behavior of Super 304H austenitic stainless steel by TEM. Corrosion Sci. 2018;130:143–152. doi:10.1016/j.corsci.2017.11.001

Zhang, ZX, Lin G, Xu Z Effects of light pre-deformation on pitting corrosion resistance of copper bearing ferrite antibacterial stainless steel. J Mater Proc Technol. 2008;205:419–424. doi:10.3390/ma13020403

Jeon S, Kim S, Lee I, Park J, Kim K, Kim J, Park Y. Effects of copper addition on the formation of inclusions and the resistance to pitting corrosion of high performance duplex stainless steels. Corrosion Sci. 2011;53:1408–1416. doi:10.1016/j.corsci.2011.01.005

Zhang J, Young DJ. Effect of copper on metal dusting of austenitic stainless steels. Corrosion Sci. 2007;49:1450–1467. doi:10.1016/j.corsci.2006.06.032

Hsu Ch, Lin K. Effects of copper and austempering on corrosion behavior of ductile iron in 3.5 PCT sodium chloride. Metallurg Mater Trans A Phys Metallurg Mater Sci. 2014;45:3:1517–1523. doi:10.1007/s11661-013-2059-2

Seo M, Hultquist G, Leygraf C, et al. The influence of minor alloying elements (Nb, Ti and Cu) on the corrosion resistivity of ferritic stainless steel in sulfuric acid solution. Corros Sci., 1986;26(949–955):957–960. doi:10.1016/0010-938X(86)90085-5

Gong L, Fu H, Zhi X. First-principles study on corrosion resistance of copper-bearing hypereutectic high chromium cast iron. Mater Today Commun. 2022;33:104345. doi:10.1016/j.mtcomm.2022.104345

Wei M, Yang B, Liu Y, et al. Research progress and prospect on erosion-corrosion of Cu-Ni alloy pipe in seawater. J Chinese Soc Corros Protect. 2016;36(6):513–521. doi:10.11902/1005.4537.2016.123

Sandra N, et al. Influence of copper slag on corrosion behavior of horizontal steel bars in reinforced concrete column specimen due to chloride-induced corrosion. Construc Build Mater. 2020;255:119265. doi:10.1016/j.conbuildmat.2020.119265

Aperador W, Bautista-Ruiz J, Caicedo J. Wear synergy of copper-iron mixtures processed by powder metallurgy. Rasayan J Chem. 2021:193–199. doi:10.31788/RJC.2021.1456678

Lapierre-Boire L-P, Blais C, Pelletier S, Chagnon F. Improvement of flow of an iron-copper-graphite powder mix through additions of nanoparticles. Powder Technol. 2016;299:156–167. doi:10.1016/j.powtec.2016.05.046

Fedorchenko IM, Pugina LI. Kompozitsionnyye spechennyye antifriktsionnyye materialy [Composite sintered antifriction materials]. Kyiv: Nauk, Dumka, 1980. 404 p.

Bataev IA, Stepanova NV, Bataev AA, Nikulina AA, Razumakov AA. Peculiarities of the precipitation of nanosized ε-phase copper particles in ferrite plates of lamellar pearlite. Phys Metals Metallograph. 2016;117(9):901–905. doi:10.1134/S0031918X16090015

Shubhank K, Kang Y. Critical evaluation and the termodynamic optimization of Fe–Cu, Cu–C, Fe–C binary systems and Fe–Cu–C ternary system. Calphad. 2014;45:127–137. doi:10.1016/j.calphad.2013.12.002

Stepanova NV, Mikhalev RI, Tarasova TD. Peculiarities of copper precipitation in hypereutectoid steels. Metallurg. 2023;66(11–12):1388–1400. doi:10.1007/s11015-023-01454-y

Chichinadze AV, Brown ED, Boucher NA. Basics of tribology (friction, wear, lubrication). 2nd ed. processing, and additional [Basics of tribology (friction, wear, lubrication). 2nd ed. processing, and additional] Moscow: Mechanical engineering; 2001. 664 p. Russian.

Kragelsky IV. Friction and wear. Edition 2, revised and expanded [Friction and wear. Edition 2, revised and expanded] Moscow: Mechanical engineering; 1968. 480 p. Russian.

DOI: https://doi.org/10.15826/chimtech.2023.10.3.15

Copyright (c) 2023 Natalia V. Stepanova, Elena A. Lozhkina

This work is licensed under a Creative Commons Attribution 4.0 International License.

Chimica Techno Acta, 2014–2025

eISSN 2411-1414

Copyright Notice