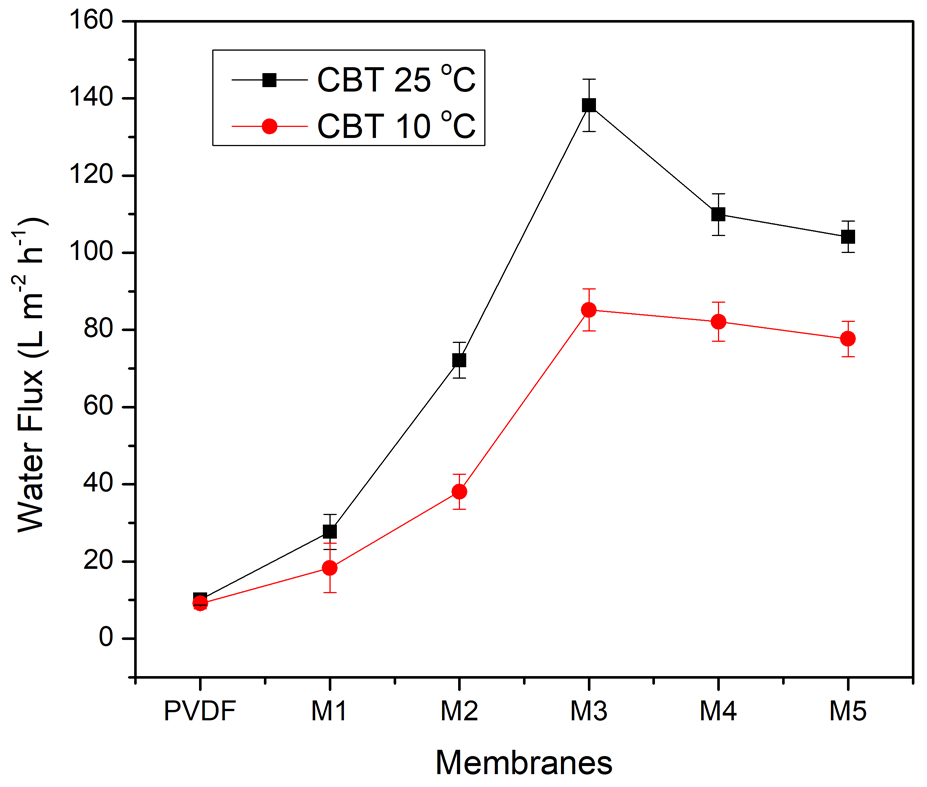

Effects of coagulant bath temperature toward separation performance and antifouling properties of PVDF/CA membranes for filtration of dyes

Abstract

Keywords

Full Text:

PDFReferences

Saljoughi E, Amirilargani M, Mohammadi T. Effect of PEG additive and coagulation bath temperature on the morphology, permeability and thermal/chemical stability of asymmetric CA membranes. Desalination. 2010;262(1–3):72–78. doi:10.1016/j.desal.2010.05.046

Baker RW. Membrane technology and application second edition. California: John Wiley & Sons, Ltd; 2004. doi:10.1002/0470020393

Mulder M. Basic principles of membrane technology. Netherlands: Kluwer Academic Publishers; 1996. doi:10.1007/978-94-009-1766-8

Feng C, Wang R, Zhang H, Shi L. Diverse morphologies of PVDF hollow fiber membranes and their performance analysis as gas/liquid contactors. J Appl Polym Sci. 2011;119(3):1259–1267. doi:10.1002/app.30250

Liu F, Hashim NA, Liu Y, Abed MRM, Li K. Progress in the production and modification of PVDF membranes. J Memb Sci. 2011;375(1–2):1–27. doi:10.1016/j.memsci.2011.03.014

Wang D, Li K, Teo WK. Preparation and characterization of polyvinylidene fluoride (PVDF) hollow fiber membranes. J Memb Sci. 1999;163(2):211–220. doi:10.1016/S0376-7388(99)00181-7

Baroña GNB, Cha BJ, Jung B. Negatively charged poly(vinylidene fluoride) microfiltration membranes by sulfonation. J Memb Sci. 2007;290(1–2):46–54. doi:10.1016/j.memsci.2006.12.013

Ma J, Wang Z, Pan M, Guo Y. A study on the multifunction of ferrous chloride in the formation of poly(vinylidene fluoride) ultrafiltration membranes. J Memb Sci. 2009;341(1–2):214–24. doi:10.1016/j.memsci.2009.06.008

Ong YK, Widjojo N, Chung TS. Fundamentals of semi-crystalline poly(vinylidene fluoride) membrane formation and its prospects for biofuel (ethanol and acetone) separation via pervaporation. J Memb Sci. 2011;378(1–2):149–162. doi:10.1016/j.memsci.2011.04.037

Hou D, Wang J, Qu D, Luan Z, Ren X. Fabrication and characterization of hydrophobic PVDF hollow fiber membranes for desalination through direct contact membrane distillation. Sep Purif Technol. 2009;69(1):78–86. doi:10.1016/j.seppur.2009.06.026

Yang X, Wang R, Shi L, Fane AG, Debowski M. Performance improvement of PVDF hollow fiber-based membrane distillation process. J Memb Sci. 2011;369(1–2):437–447. doi:10.1016/j.memsci.2010.12.020

Atchariyawut S, Feng C, Wang R, Jiraratananon R, Liang DT. Effect of membrane structure on mass-transfer in the membrane gas-liquid contacting process using microporous PVDF hollow fibers. J Memb Sci. 2006;285(1–2):272–281. doi:10.1016/j.memsci.2006.08.029

Peng J, Su Y, Chen W, Shi Q, Jiang Z. Effects of coagulation bath temperature on the separation performance and antifouling property of poly(ether sulfone) ultrafiltration membranes. Ind Eng Chem Res. 2010;49(10):4858–4864. doi:10.1021/ie9018963

Wang D, Li K, Teo WK. Porous PVDF asymmetric hollow fiber membranes prepared with the use of small molecular additives. J Memb Sci. 2000;178(1–2):13–23. doi:10.1016/S0376-7388(00)00460-9

Yuan GL, Xu ZL, Wei YM. Characterization of PVDF-PFSA hollow fiber UF blend membrane with low-molecular weight cut-off. Sep Purif Technol. 2009;69(2):141–148. doi:10.1016/j.seppur.2009.07.011

Conesa A, Gumí T, Palet C. Membrane thickness and preparation temperature as key parameters for controlling the macrovoid structure of chiral activated membranes (CAM). J Memb Sci. 2007;287(1):29–40. doi:10.1016/j.memsci.2006.10.006

Kumar M, Ulbricht M. Novel ultrafiltration membranes with adjustable charge density based on sulfonated poly(arylene ether sulfone) block copolymers and their tunable protein separation performance. Polymer. 2014;55(1):354–365. doi:10.1016/j.polymer.2013.09.003

Torrestiana-Sanchez B, Ortiz-Basurto RI, Brito-De E, Fuente L. Effect of nonsolvents on properties of spinning solutions and polyethersulfone hollow fber ultrafiltration membranes. J Memb Sci. 1999;152:19–28. doi:10.1016/S0376-7388(98)00172-0

Cheng LP. Effect of temperature on the formation of microporous PVDF membranes by precipitation from 1-Octanol/DMF/PVDF and water/ DMF/PVDF systems. Macromolecules. 1999;32(20):6668–6674. doi:10.1021/ma990418l

Saljoughi E, Amirilargani M, Mohammadi T. Effect of poly(vinyl pyrrolidone) concentration and coagulation bath temperature on the morphology, permeability, and thermal stability of asymmetric cellulose acetate membranes. J Appl Polym Sci. 2009;111(5):2537–2544. doi:10.1002/app.29354

Wang GJ, Chu LY, Zhou MY, Chen WM. Effects of preparation conditions on the microstructure of porous microcapsule membranes with straight open pores. J Memb Sci. 2006;284(1–2):301–312. doi:10.1016/j.memsci.2006.07.048

Wang X, Zhang L, Sun D, An Q, Chen H. Effect of coagulation bath temperature on formation mechanism of poly(vinylidene fluoride) membrane. J Appl Polym Sci. 2008;110(3):1656–1663. doi:10.1002/app.28169

Shin SJ, Kim JP, Kim HJ, Jeon JH, Min BR. Preparation and characterization of polyethersulfone microfiltration membranes by a 2-methoxyethanol additive. Desalination. 2005;186(1–3):1–10. doi:10.1016/j.desal.2005.03.092

Hossein Razzaghi M, Safekordi A, Tavakolmoghadam M, Rekabdar F, Hemmati M. Morphological and separation performance study of PVDF/CA blend membranes. J Memb Sci. 2014;470:547–557. doi:10.1016/j.memsci.2014.07.026

Reza M, Pramono E, Radiman CL. Improving Separation Performance of PVDF Ultrafiltration Membranes by Blending with Cellulose Acetate. J Chem Chem Eng. 2023;42(3):1017–29. doi:10.30492/ijcce.2022.550394.5221

Loh CH, Wang R. Effects of additives and coagulant temperature on fabrication of high performance PVDF/Pluronic F127 blend hollow fiber membranes via nonsolvent induced phase separation. Chin J Chem Eng. 2012;20(1):71–79. doi:10.1016/S1004-9541(12)60365-6

Saraswathi MSSA, Rana D, Alwarappan S, Gowrishankar S, Vijayakumar P, Nagendran A. Polydopamine layered poly (ether imide) ultrafiltration membranes tailored with silver nanoparticles designed for better permeability, selectivity and antifouling. J Ind Eng Chem. 2019;76:141–149. doi:10.1016/j.jiec.2019.03.014

Miller DJ, Kasemset S, Paul DR, Freeman BD. Comparison of membrane fouling at constant flux and constant transmembrane pressure conditions. J Memb Sci. 2014;454:505–515. doi:10.1016/j.memsci.2013.12.027

Vadivelan V, Vasanth Kumar K. Equilibrium, kinetics, mechanism, and process design for the sorption of methylene blue onto rice husk. J Colloid Interface Sci. 2005;286(1):90–100. doi:10.1016/j.jcis.2005.01.007

Nair VR, Shetty Kodialbail V. Floating bed reactor for visible light induced photocatalytic degradation of Acid Yellow 17 using polyaniline-TiO2 nanocomposites immobilized on polystyrene cubes. Environ Sci Pollut Res Int. 2020;27(13):14441–14453. doi:10.1007/s11356-020-07959-2

Jayalakshmi A, Rajesh S, Mohan D. Fouling propensity and separation efficiency of epoxidated polyethersulfone incorporated cellulose acetate ultrafiltration membrane in the retention of proteins. Appl Surf Sci. 2012;258(24):9770–9781. doi:10.1016/j.apsusc.2012.06.028

Lapointe JF, Gauthier SF, Pouliot Y, Bouchard C. Characterization of interactions between β-lactoglobulin tryptic peptides and a nanofiltration membrane: Impact on the surface membrane properties as determined by contact angle measurements. J Memb Sci. 2005;261(1–2):36–48. doi:10.1016/j.memsci.2005.03.030

Khayet M, Cojocaru C, García-Payo MC. Experimental design and optimization of asymmetric flat-sheet membranes prepared for direct contact membrane distillation. J Memb Sci. 2010;351(1–2):234–245. doi:10.1016/j.memsci.2010.01.057

Wongchitphimon S, Wang R, Jiraratananon R, Shi L, Loh CH. Effect of polyethylene glycol (PEG) as an additive on the fabrication of polyvinylidene fluoride-co-hexafluropropylene (PVDF-HFP) asymmetric microporous hollow fiber membranes. J Memb Sci. 2011;369(1–2):329–338. doi:10.1016/j.memsci.2010.12.008

Yeow ML, Liu YT, Li K. Isothermal Phase Diagrams and Phase-Inversion Behavior of Poly(vinylidene fluoride)/Solvents/Additives/Water Systems. J Appl Polym Sci. 2003;90:2150–2155. doi:10.1002/app.12846

Reza M, Pramono E, Cyntia LR. Improving Separation Performance of PVDF Ultrafiltration Membranes by Blending with Cellulose Acetate. J Chem Chem Eng. 2023;42(3):1017–1029. doi:10.30492/ijcce.2022.550394.5221

Li J, Ren LF, Zhou HS, Yang J, Shao J, He Y. Fabrication of superhydrophobic PDTS-ZnO-PVDF membrane and its anti-wetting analysis in direct contact membrane distillation (DCMD) applications. J Memb Sci. 2021;620. doi:10.1016/j.memsci.2020.118924

Lafuma A, Quéré D. Superhydrophobic states. Nat Mater. 2003;2(7):457–460. doi:10.1038/nmat924

Curcio E, Fontananova E, Di Profio G, Drioli E. Influence of the structural properties of poly(vinylidene fluoride) membranes on the heterogeneous nucleation rate of protein crystals. J Phys Chem B. 2006;110(25):12438–12445. doi:10.1021/jp061531y

Umam K, Sagita F, Pramono E, Ledyastuti M, Kadja GTM, Radiman CL. Polyvinylidenefluoride (PVDF)/surface functionalized-mordenite mixed matrix membrane for congo red dyes removal: Effect of types of organosilane. JCIS Open. 2023;11. doi:10.1016/j.jciso.2023.100093

Huang FL, Wang QQ, Wei QF, Gao WD, Shou HY, Jiang SD. Dynamic wettability and contact angles of poly(vinylidene fluoride) nanofiber membranes grafted with acrylic acid. Express Polym Lett. 2010;4(9):551–558. doi:10.3144/expresspolymlett.2010.69

Hebbar RS, Isloor AM, Ismail AF. Contact Angle Measurements. In: Membrane Characterization. Elsevier Inc. 2017; 219–255. doi:10.1016/B978-0-444-63776-5.00012-7

Chen Y, Tian M, Li X, Wang Y, An AK, Fang J, et al. Anti-wetting behavior of negatively charged superhydrophobic PVDF membranes in direct contact membrane distillation of emulsified wastewaters. J Memb Sci. 2017;535:230–238. doi:10.1016/j.memsci.2017.04.040

Breite D, Went M, Prager A, Schulze A. Tailoring membrane surface charges: A novel study on electrostatic interactions during membrane fouling. Polymers. 2015;7(10):2017–30. doi:10.3390/polym7101497

Tran TT Van, Kumar SR, Lue SJ. Separation mechanisms of binary dye mixtures using a PVDF ultrafiltration membrane: Donnan effect and intermolecular interaction. J Memb Sci. 2019;575:38–49. doi:10.1016/j.memsci.2018.12.070

Ghaffar A, Zhang L, Zhu X, Chen B. Porous PVdF/GO nanofibrous membranes for selective separation and recycling of charged organic dyes from water. Environ Sci Technol. 2018;52(7):4265–74. doi:10.1021/acs.est.7b06081

Oladoye PO, Ajiboye TO, Omotola EO, Oyewola OJ. Methylene blue dye: Toxicity and potential elimination technology from wastewater. Res Eng. 2022;16. doi:10.1016/j.rineng.2022.100678

Adar E. Removal of Acid Yellow 17 from textile wastewater by adsorption and heterogeneous persulfate oxidation. Int J Environ Sci Technol. 2021;18(2):483–498. doi:10.1007/s13762-020-02986-5

Razzaghi MH, Tavakolmoghadam M, Rekabdar F, Oveisi F. Investigation of the effect of coagulation bath composition on PVDF/CA membrane by evaluating critical flux and antifouling properties in lab-scale submerged MBR. Water Environ J. 2018;32(3):366–376. doi:10.1111/wej.12334

Hossein Razzaghi M, Safekordi A, Tavakolmoghadam M, Rekabdar F, Hemmati M. Morphological and separation performance study of PVDF/CA blend membranes. J Memb Sci. 2014;470:547–57. doi:10.1016/j.memsci.2014.07.026

Duong PHH, Nunes SP, Chung TS. Dual-skinned polyamide/poly(vinylidene fluoride)/cellulose acetate membranes with embedded woven. J Memb Sci. 2016;520:840–849. doi:10.1016/j.memsci.2016.08.047

Du J, Li N, Tian Y, Zhang J, Zuo W. Preparation of PVDF membrane blended with graphene oxide-zinc sulfide (GO-ZnS) nanocomposite for improving the anti-fouling property. J Photochem Photobiol A Chem. 2020;400. doi:10.1016/j.jphotochem.2020.112694

DOI: https://doi.org/10.15826/chimtech.2024.11.2.01

Copyright (c) 2024 Muhammad Reza, Ratu Fazlia Inda Rahmayani, Cynthia Linaya Radiman

This work is licensed under a Creative Commons Attribution 4.0 International License.

© Website Chimica Techno Acta, 2014–2024

ISSN 2411-1414 (Online)

This journal is licensed under a Creative Commons Attribution 4.0 International