High-temperature electrochemistry of calcium

Abstract

Electrolytically produced calcium is one of the most demanded materials in obtaining pure materials. At the same time, the existing technologies and devices for the electrolytic production of calcium were developed in the last century, and at present there are practically no works aimed at optimizing them. However, increasing the capacity and efficiency of existing devices for the production of calcium is in demand. To analyze possible ways to improve calcium production, a comprehensive understanding of the processes occurring at the electrodes and in the electrolyte during electrolytic production of calcium is required.

This review briefly outlines the main points concerning the electrolytic production of calcium: from a brief history of the development of methods for the electrolytic production of calcium and established ideas about its physicochemical processes to information about new developments using the electrolysis of CaCl2-based melts. Review content: brief history of process development; base electrolyte for calcium production, including preparation of CaCl2 and influence of additions on it physicochemical properties; data on calcium solubility in CaCl2; information about alternative electrolytes for calcium production; short description of electrode processes in the CaCl2-based melts; proposed technologies and devices for the electrolytic production of calcium.

Keywords

Full Text:

PDFReferences

Doronin NA. Kal'tsiy [Calcium]. Atomizdat: Moscow; 1962. Russian. 191 p.

Rodyakin V.V. Kal'tsiy, yego soyedineniya i splavy [Calcium, its compounds and alloys]. Metallurgy: Moscow; 1967. Russian. 186 p.

Zaikov YuP, Shurov NI, Suzdaltsev AV. Vysokotemperaturnaya elektrohimia caltsiya [High-temperature electrochemistry of calcium]. RIO UB RAS: Yekaterinburg; 2013. 200 p. Russian. ISBN 978-507691-2350-4.

Emsley J. The elements. Oxford University Press: New York; 1998. 292 p. ISBN 978-01985-5818-7.

Turkdogan ET. Physical chemistry of high temperature technology. Academic Press: New York; 1980. 447 p.

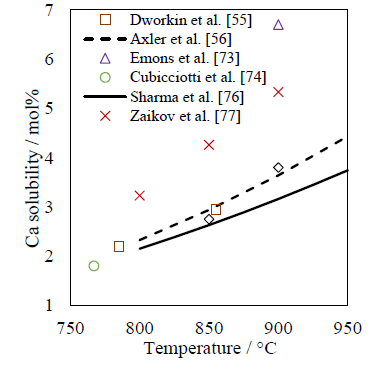

Emons HH, Anders D, Roewer G, Vogt H, Untersuchungen an erdalkalimetall -erdulkalimetallhalogenid systemen. VIII. Der einfluss des stickstoffs auf erdalkalimetallhalogenid - systeme, Z. Anorg. Allgem. Chemie 333(1-3) (1964) 99-107. https://doi.org/10.1002/zaac.19643330114. Deutsch.

Ouchi T, Kim H, Spatocco BL, Sadoway DR, Calcium-based multi-element chemistry for grid-scale electrochemical energy storage, Nature Communications. 7 (2016) 10999. https://doi.org/10.1038/ncomms10999

Richter D, Emons HH, Auflosung der erdalkalimetalle in ihren geschmolzenen halogeniden, Z. Chemie. 6(11) (1966) 407-416. Deutsch. https://doi.org/10.1002/zfch.19660061103

Ellery A, Mellor I, Wanjara P, Conti M, Metalysis Fray Farthing Chen process as a strategic lunar in situ resource utilization technology, New Space. 10(2) (2022) 224-238. https://doi.org/10.1089/space.2021.0047

Squires LN, Lessing P, Direct chemical reduction of neptunium oxide to neptunium metal using calcium and calcium chloride, J. Nucl. Materials. 471 (2016) 65-68. https://doi.org/10.1016/j.jnucmat.2016.01.007

Iizuka M, Inoue T, Ougier M, Glatz JP, Electrochemical reduction of (U, Pu)O2 in molten LiCl and CaCl2 electrolytes, J. Nucl. Sci. Technol. 44 (2007) 801-813. https://doi.org/10.1080/18811248.2007.9711869

Zhao J, Zhu H, Wang L, Song M et al., Effect of CaO/Al2O3 ratio on desulphurization and non-metallic inclusions in low-density steel, Ironmaking & Steelmaking. 49(3) (2022) 302-310. https://doi.org/10.1080/03019233.2021.1993695.

Liu H, Kang J, Zhao X, Zhang C et al., Influence of Ca treatment on particle-microstructure relationship in heat-affected zone of shipbuilding steel with Zr-Ti deoxidation after high-heat-input welding, J. Iron Steel Res. Int. 29 (2022) 1291-1298. https://doi.org/10.1007/s42243-022-00791-7

Rong Z, Liu H, Zhang P, Wang F et al., The formation mechanisms and evolution of multi-phase inclusions in Ti-Ca deoxidized offshore structural steel, Metals. 12 (2022) 511. https://doi.org/10.3390/met12030511

Hosein ID, The promise of calcium batteries: Open perspectives and fair comparisons, ACS Energy Letters. 6 (2021) 1560-1565. https://doi.org/10.1021/acsenergylett.1c00593

Stievano L, De Meatza I, Bitenc J, Cavallo et al. Emerging calcium batteries, J. Power Sources. 482 (2021) 228875. https://doi.org/10.1016/j.jpowsour.2020.228875

Ji B, He H, Yao W, Tang Y, Recent advances and perspectives on calcium-ion storage: Key materials and devices, Advanced Materials. 33(2) (2021) 2005501. https://doi.org/10.1002/adma.202005501

Arroyo-de Dompablo ME, Ponrouch A, Johansson P, Rosa Palacin M, Achievements, challenges, and prospects of calcium batteries, Chemical Reviews. 120 (2020) 6331-6357. https://doi.org/10.1021/acs.chemrev.9b00339

Yu X, Boyer MJ, Hwang GS, Manthiram A, Toward a reversible calcium-sulfur battery with a lithium-ion mediation approach, Advanced Energy Materials. 9 (2019) 1803794. https://doi.org/10.1002/aenm.201803794

Reinsberg Ph, Bondue ChJ, Baltruschat H, Calcium-oxygen batteries as a promising alternative to sodium-oxygen batteries, The J. Phys. Chem. C. 120 (2016) 22179-22185. https://doi.org/10.1021/acs.jpcc.6b06674

Bhattacharyya R, El-Emam RS, Khalid F, Multi-criteria analysis for screening of reversible metal hydrides in hydrogen gas storage and high-pressure delivery applications, Int. J. Hydrogen Energy. 47 (2022) 19718-19731. https://doi.org/10.1016/j.ijhydene.2021.12.168

Ropp RC. Encyclopedia of the alkaline earth compounds. Elsevier B.V.: Oxford; 2012. 1190 p. https://doi.org/10.1016/C2012-0-00777-6

Kotsar ML, Talanov AA, Thermodynamics of high-purity calcium production, Rus. J. Inorg. Chem. 61 (2016) 344-350. https://doi.org/10.1134/S003602361603013X

Tarasov VP, Kropachev AN, Kulifeev VK, Overview of contemporary scientific research results in calcium metallurgy, Tsvetnye Metally 9 (2015) 73-77. https://doi.org/10.17580/tsm.2015.09.12

Polat BT, Öner İE, Kan S, Benzeşik K, Yücel O, Fused calcium aluminate production from aluminum white dross residue, J. Sustainable Metallurgy. 8(2) (2022) 851-862. https://doi.org/10.1007/s40831-022-00532-w

Kulifeev VK, Kropachev AN, Tarasov VP, Thermodynamic investigations and substantiation of the aluminothermic fabrication method of calcium, Rus. J. Non-Ferrous Metals. 57(1) (2016) 7-13. https://doi.org/10.3103/S1067821216010090

El-Sadek MH, El-Barawy K, Morsi IM, Production of calcium metal by aluminothermic reduction of Egyptian limestone ore, Canadian Metallurgical Quarterly. 58(2) (2018) 1-10. https://doi.org/10.1080/00084433.2018.1544343

Taşyürek KC, Bugdayci M, Yucel O, Reduction conditions of metallic calcium from magnesium production residues, Metals. 8(6) (2018) 383. https://doi.org/10.3390/met8060383

Davy H. Electro-chemical researches on the decomposition of the earths; with observations on the metals obtained from the alkaline earths, and on the amalgam procured from ammonia. Philosophical Trans. Royal Society of London. 98 (1808) 333-370. https://doi.org/10.1098/rstl.1808.0023

Zutter H, Redlich C, Verfahren der elektrolytischen darstellung von erdalkalimetallen, namentlich von calcium auf feuerflussigem wege in kompakter, insbesondere stangenform, Patent DE155433, published 10.05.1903. Deutsch.

Mikulinsky AS, Continuous vacuum electric furnace, Soviet Union patent SU154966, 1960 May 16.

Threadgill WD, Preparation of metallic calcium be electrolysis of calcium oxide dissolved in molten calcium chloride, J. Electrochem. Soc. 111 (1964) 1408-1411. https://doi.org/10.1149/1.2426015

Talanov AA, Kotsar ML, Ilyenko EV, Kiverin VL et al. Analysis of the technical and economic indicators of modern calcium production, Tsvetnye Metally. 1 (2013) 57-60

Claquesin J, Gibilaro M, Massot L, Lemoine O et al, Thermodynamic properties of CaCl2–CaF2–CaO system: Phase diagram investigation, Materials Sciences and Applications. 12 (2021) 139-151. https://doi.org/10.4236/msa.2021.124009

Tomkute V, Solheim A, Olsen E, CO2 capture by CaO in molten CaF2–CaCl2: optimization of the process and cyclability of CO2 capture, Energy & Fuel. 28 (20014) 5345-5353. https://doi.org/10.1021/EF5010896

Boghosian S, Godo A, Mediaas H, Ravlo W et al. Oxide complexes in alkale – alkaline – earth chloride melts, Acta Chem. Scand. 45 (1991) 145-157. https://doi.org/10.3891/acta.chem.scand.45-0145

Wang Sh, Wang W, Li Sh, Cao Sh, Cathodic behavior of molten CaCl2–CaO and CaCl2–NaCl–CaO, Int. J. Minerals, Metallurgy, and Materials. 17 (2010) 791-794. https://doi.org/10.1007/s12613-010-0391-8

Pinching GD, Bates RG. Purification of sodium chloride and potassium chloride for use in electrochemical work, and the determination of small amounts of bromide, J. Research of the National Bureau of Standards Research. 37 (1946) RPl749. https://doi.org/10.6028/jres.037.020

Laitinen H, Ferguson W, Osteryoung R, Preparation of pure fused lithium chloride-potassium chloride eutectic solvent, J. Electrochem. Soc. 104 (1957) 516 https://doi.org/10.1149/1.2428639

Kurley JM, Halstenberg PhW, Mc Alister A, Raiman S, Dai Sh, Mayes RT, Enabling chloride salts for thermal energy storage: implications of salt purity, RSC Advances. 9 (2019) 25602. https://doi.org/10.1039/c9ra03133b

Shishkin VYu, Mityayev VS. Ochistka galogenidov shchelochnykh metallov metodom zonnoy plavki [Purification of alkali metal halides by zone melting], Proc. Academy of Sciences of the USSR. Inorganic materials 18(11) (1982) 1917-1918. Russian.

Nikolaev AYu, Mullabaev AR, Suzdaltsev AV, Kovrov VA et al., Purification of alkali-metal chlorides by zone recrystallization for the use in pyrochemical processing of spent nuclear fuel, Atomic Energy. 131(4) (2022) 195-201. https://doi.org/10.1007/s10512-022-00865-5

Smirnov M, Korzun I, Oleynikova V, Hydrolysis of molten alkali chlorides, bromides and iodides. 33 (1988) 781-788. https://doi.org/10.1016/S0013-4686(98)80007-8

Swider S, Lam S, Motakef S, Donohoe E et al. Impurity segregation in zone-refined precursors for crystalline halide scintillators, Nuclear Instruments and Methods in Physics Research A. 784 (2015) 5-8. 45. https://doi.org/10.1016/j.nima.2014.11.048

Mukherjee A, Kumaresan R, Ghosh S, Redox behaviour of CaCl2 melts in presence of moisture as impurity. Part I: Cyclic voltammetry, J. Electroanal. Chem. 902 (2021) 115778. https://doi.org/10.1016/j.jelechem.2021.115778

Yin H, Gao L Zhu H., Mao X et al. On the development of metallic inert anode for molten CaCl2–CaO system, Electrochim. Acta. 56 (2011) 3296-3302. https://doi.org/10.1016/j.electacta.2011.01.026.

Threadgill WD, The calcium chloride - calcium oxide fused salt electrolytic system: solubilities, metal contents, and freezing point, J. Electrochem. Soc. 112(6) (1965) 632-633. https://doi.org/10.1149/1.2423626

Wenz DA, Jonson I, Wolson RD, CaCl2-rich region of the CaCl2–CaF2–CaO system, J. Chem. Eng. Data. 14 (1969) 250-252. https://doi.org/10.1021/JE60041A027

Wang S, Zhang F, Lin X, Zhang L, CaO solubility and activity coefficient in molten salt CaCl2–X (X=0, NaCl, KCl, SrCl2, BaCl2 and LiCl), Thermochim. Acta. 470 (2008) 105-107. https://doi.org/10.1016/j.tca.2008.02.007

Antonov BD, Stepanov VP, Kulik NP, Formation of colloidal particles in melts of the CaCl2–CaO system. High-temperature X-ray diffraction study, Colloid Journal of the Russian Academy of Sciences. 60(4) (1998) 442-445.

Perry GS, Macdonald LG, Role of CaCl2 in the reduction of PuO2, J. Nucl. Materials. 130 (1985) 234-241. https://doi.org/10.1016/0022-3115(85)90312-5

Zinchenko VF, Timukhin EV, Pavlinchuk SA, Nechiporenko AV et al., Basicity–acidity and solubility of metal fluorides and oxides in salt melts, Rus. J. Electrochem. 48(10) (2012) 995-999. https://doi.org/10.1134/S102319351210014X

Solodkova MV, Zhuravlev VI, Volkovich AV, Solubility of calcium, strontium and barium oxides in chloride and chloride-fluoride melts, ChemChemTech. 52(6) (2009) 8-12.

Janz GJ, Thermodynamic and transport properties for molten salts, American Chemical Society and the American Institute of Physics: Michigan; 1988. 309 p. ISBN 978-0883185872.

Dworkin AS, Bronstein HR, Bredig MA, Ionic melts as solvent for electronic conductors, Discuss. Faraday Society. 32 (1961) 188-196. https://doi.org/10.1039/DF9613200188

Axler KM, De Poorter GL, Solubility studies of the Ca–СаО–CaCl2 system, Materials Science Forum. 73-75 (1991) 19-24. https://doi.org/10.4028/www.scientific.net/MSF.73-75.19

Shaw S, Watson R, Solubility of calcium in CaCl2–CaO, ECS Transactions. 16(49) (2009) 301-308. https://doi.org/10.1149/1.3159334

Freidina EB, Fray DJ, Study of the ternary system СаCl2–NaCl–CaO by DSC, Thermochim. Acta. 356 (2000) 97-100. https://doi.org/10.1016/S0040-6031(00)00419-6

Kosnyrev GT, Desyatnik VN, Kern IA, Nosonova EN, Obshchaya shchelochnost' i rastvorimost' CaO v rasplavakh CaCl2–KCl–NaCl [Total alkalinity and solubility of CaO in CaCl2–KCl–NaCl melts], Rasplavy. 2 (1990) 120-123. Russian.

Cherginets VL, Khimiya oksosoyedineniy v ionnykh rasplavakh [Chemistry of oxo compounds in ionic melts]. National Academy of Sciences of Ukraine: Kharkov; 2004. 279 p. Russian. ISBN 966-02-3244-6.

Volkovich AV, Ermakov DS, Zhuravlev VI, Kvantovo-khimicheskoye modelirovaniye galogenidnykh i oksidno-galogennykh kompleksnykh ionov kal'tsiya [Quantum-chemical modeling of halide and oxide-halide complex calcium ions], Rasplavy. 1 (1999) 49-54. Russian.

Grjotheim K, Holm JL, Lillebuen B, Oye HA, Surface tension of liquid binary and ternary chloride mixtures, Acta Chem. Scand. 26 (1972) 2050-2062. https://doi.org/10.3891/acta.chem.scand.26-2050

Brautigam G, Emons HH, Dichten und volum in geschmolzener salzmischungen aus erdalkalimetallchlorid und alkalimetallchlorid, Z. Anorg. Allg. Chem. 394 (1972) 271-278. https://doi.org/10.1002/zaac.19723940309

Grjotheim K, Holm JL, Lillebuen B, Oye HA, Densities and excess molar volumes of binary and ternary melts of MgCl2, CaCl2 and AlkCl, Trans. Faraday Soc. 67 (1971) 640-648. https://doi.org/10.1039/TF9716700640

Dumas D, Fjeld B, Grjotheim K, Oye HA, Viscosities of some binary mixtures between MgCl2, CaCl2 and AlkCl, Acta Chem. Scand. 27 (1973) 319-328. https://doi.org/10.3891/acta.chem.scand.27-0319

Tseng M, Ricci L, Tao M, Multi-potential electropurification of a reusable CaCl2–CaF2 eutectic salt for solar-grade Si electrorefining, Separation and Purification Technology. 274 (2021) 119030. https://doi.org/10.1016/j.seppur.2021.119030

Tago Y, Endo Y, Morita K, Tsukihashi F et al, The activity of CaO in the CaO–CaCl2 and CaO–CaCl2–CaF2 systems. ISIJ International. 35(2) (1995) 127-131. https://doi.org/10.2355/isijinternational.35.127

Olsen E, Hansen M, Nygård HS, Hydrolysis of molten CaCl2–CaF2 with additions of CaO, AIMS Energy. 5(6) (2017) 873-886. https://doi.org/10.3934/energy.2017.6.873

Davy H, The Bakerian Lecture, on some chemical agencies of electricity, Philosophical Trans. Royal Society of London. 97 (1807) 1-57. https://doi.org/10.1098/rstl.1807.0001

Delimarsky YuK, Elektrokhimiya ionnykh rasplavov [Electrochemistry of ionic melts], Metallurgy: Moscow; 1978. 248 p. Russian.

Guntz A, Benoit F, Sur les sous - sels alcalino – terreux, Bull. Soc. Chim. France. 35 (1924) 709-728.

Peterson DT, Hinkebein JA, Equilibria in the reaction of barium with calcium chloride, J. Phys. Chem. 63(9) (1959) 1360-1363. https://doi.org/10.1021/J150579A004

Emons HH, Grothe W, Hellmold P, Zur frage der existenz von erdalkalimettallsubhalogeniden, Z. Anorg. Allgem. Chem. 323(3-4) (1963) 114-125. Deutsch. https://doi.org/10.1002/zaac.19633230304

Cubicciotti DD, Thurmond CD, Metal-salt interactions at high temperatures: solubilities of some alkaline earth metals in their halides, J. Amer. Chem. Soc. 71 (1949) 2149-2153. https://doi.org/10.1021/JA01174A067

Lichter BD, Bredig MA, Solid and liquid phase miscibility of calcium metal and calcium fluoride, J. Electrochem. Soc. 112(5) (1965) 506-510. https://doi.org/10.1149/1.2423584

Sharma RA, The solubilities of calcium in liquid calcium chloride in equilibrium with calcium-copper alloys, J. Phys. Chem. 74 (1970) 3896-3900. https://doi.org/10.1021/J100716A009

Dosaj V, Aksaranan Ch, Morris DR, Thermodynamic properties of the calcium + calcium chloride system measured by an electrochemical technique, J. Chem. Soc., Faraday Trans. 71 (1975) 1083-1098. https://doi.org/10.1039/F19757101083

Blender M (ed.), Molten salts chemistry, Interscience Publishers: New York; 1964. p. 367-425. https://doi.org/10.2172/4658668

Dworkin AS, Bronstein HR, Bredig MA, The electrical conductivity of solutions of metals in their molten halides. VIII. Alkaline earth metal systems, J. Phys. Chem. 70 (1966) 2384-2388. https://doi.org/10.1021/j100879a048

Lovering D (ed.), Molten Salt Technology, Plenum Press: London-New York; 1982. p. 153-183. https://doi.org/10.1007/978-1-4757-1724-2_7

Sychev AG, Nikulin NA, Zaikov YuP, Ivanovskii LE, Issledovaniye katodnykh protsessov v rasplave khlorida kal'tsiya [Investigation of cathode processes in molten calcium chloride], Rasplavy. 6 (1992) 32-37. Russian.

Kovalevskii RA. Electrode processes at the indifferent electrode in dilute solutions of alkali and alkaline earth metals in their molten chlorides [dissertation]. Yekaterinburg (Russia): Institute of High Temperature Electrochemistry UB RAS. 1992.

Zobnin EV, Technology of electrolytic production of copper-calcium alloy [dissertation]. Yekaterinburg (Russia): Institute of High Temperature Electrochemistry UB RAS. 1998.

Chen GZ, Fray DJ, Farthing TW, Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride, Nature. 407 (2000) 361-363. https://doi.org/10.1038/35030069

Sri Maha Vishnu D, Sanil N, Shakila L, Panneerselvam G et al., A study of the reaction pathways during electrochemical reduction of dense Nb2O5 pellets in molten CaCl2 medium, Electrochimica Acta. 100 (2013) 51-62. https://doi.org/10.1016/j.electacta.2013.03.135

Wang D, Jin X, Chen GZ, Solid state reactions: an electrochemical approach in molten salts, Annual Reports Section C. 104 (2008) 189-234. https://doi.org/10.1039/B703904M

Alexander DTL, Schwandt C, Fray DJ, The electro-deoxidation of dense titanium dioxide precursors in molten calcium chloride giving a new reaction pathway, Electrochim. Acta. 56 (2011) 3286-3295. https://doi.org/10.1016/j.electacta.2011.01.027

Yan XY, Fray DJ, Electrochemical studies on reduction of solid Nb2O5 in molten CaCl2–NaCl eutectic II. Cathodic processes in electrode oxidation of solid Nb2O5, J. Electrochem. Soc. 152 (2005) E308-E318. https://doi.org/10.1149/1.2006567

Yan XY, Fray DJ, Direct electrolytic reduction of solid alumina using molten calcium chloride-alkali chloride electrolytes, J. Appl. Electrochem. 39 (2009) 1349-1360. https://doi.org/10.1007/S10800-009-9808-3

Peng J, Li G, Chen H, Wang D, Jin X, Chen GZ, Cyclic voltammetry of ZrO2 powder in the metallic cavity electrode in molten CaCl2, J. Electrochem. Soc. 157 (2010) F1-F9. https://doi.org/10.1149/1.3244568

Talanov AA, Kotsar ML, Konshin RS, Kiverin VL, Calcium distillation processes in modernized equipment with increased productivity, Tsvetnye Metally. 2 (2016) 57-61. https://doi.org/10.17580/tsm.2016.02.09

Ermakov DS, Electrochemical behavior of calcium in potassium-contained oxide-chloride melts [dissertation], Novomoskovsk (Russia), Mendeleyev University of Chemical Technology. 1999.

Zaikov YuP, Kozhevnikov V., Ivanovsky LE, Vzaimodeystviye kal'tsiya i medno-kal'tsiyevykh splavov s rasplavom khlorida kal'tsiya [Interaction of calcium and copper-calcium alloys with molten calcium chloride], Rasplavy. 3 (1989) 92-94. Russian.

Zaikov YuP, Sychev AG, Zobnin EV, Katodnye protsessy v rasplave khlorida kal'tsiya [Cathodic processes in calcium chloride melt], Rasplavy. 4 (1996) 17-23. Russian.

Barbin NM, Nekrasov VN, Ivanovsky LE, Issledovaniye ravnovesiya reaktsii CaO + CO2 ↔ CaCO3 v khloridnykh i khloridno-ftoridnykh rasplavakh [Study of the equilibrium of the reaction CaO + CO2 ↔ CaCO3 in chloride and chloride-fluoride melts], Rasplavy. 2 (1987) 108-111. Russian.

Delimarsky YuK, Grishchenko VF, Garodysky AV, Study of reactions occurring during the electrolysis of molten carbonates, Ukr. Chem. Journal. 31(1) (1965) 32-37.

Lebedev VA, Salnikov VI, Tarabaev MV, Sizikov IA et al., Kinetics and mechanism of the processes occurring at graphite anode in a CaO–CaCl2 melt, Rus. J. Applied Chem. 80 (2007) 1498-1502. https://doi.org/10.1134/S107042720709011X

Sakamura Y, Iizuka M, Applicability of nickel ferrite anode to electrolytic reduction of metal oxides in LiCl-Li2O melt at 923 K, Electrochim. Acta. 189 (2016) 74-82. https://doi.org/10.1016/j.electacta.2015.12.086

Otake K, Kinoshita H, Kikuchi T, Suzuki RO, CO2 gas decomposition to carbon by electro-reduction in molten salts, Electrochim. Acta. 100 (2013) 293-299. http://doi.org/10.1016/j.electacta.2013.02.076

Li L, Shi Zh, Gao B, Xu J et al. Electrochemical behavior of carbonate ion in the LiF–NaF–Li2CO3 system, Electrochemistry. 82 (2014) 1072-1077. https://doi.org/10.5796/electrochemistry.82.1072

Zotin IV, Zaikov YuP, Ivanovsky LE, Rastvorimost' nitrida kal'tsiya v rasplavakh CaCl2 i CaCl2–KCl [Solubility of calcium nitride in CaCl2 and CaCl2–KCl melts], Rasplavy. 1 (1989) 102-103. Russian.

Zotin IV, Zaikov YuP, Ivanovsky LE, Issledovaniye rasplavov khlorida-nitrida kal'tsiya metodom EDS [Study of calcium chloride-nitride melts by the EMF method], Rasplavy. 6 (1989) 114-117. Russian.

Bonomi A, Hadat M, Breda F, Electrochemical studies on ionic nitride solution in molten salts, J. Electrochem. Soc. 126 (1979) 248-251. https://doi.org/10.1149/1.2129013

Zaikov YuP, Molostov OG, Batukhtin VP, Ivanovsky LE, Germetichnyy elektrolizer dlya polucheniya medno-kal'tsiyevogo splava [Hermetic electrolytic cell for obtaining copper-calcium alloy], Rasplavy. 3 (1999) 72-79. Russian.

Zaikov YuP, Molostov OG, Batukhtin VP, Ivanovsky LE, Primeneniye impul'snogo toka pri proizvodstve medno-kal'tsiyevogo splava elektrolizom rasplavov [The use of pulsed current in the production of a copper-calcium alloy by electrolysis of melts], Rasplavy. 1 (2000) 43-48.

Kondo H, Asaki Z, Kond Y, Hydrolisic of fused calcium chloride of high temperature, Metall. Mat. Trans. B. 9 (1978) 477-483. https://doi.org/10.1007/BF02654424

Straka M, Lisý F, Szatmáry L. Electrodeposition of uranium by pulse electrolysis in molten fluoride salts. Molten salts chemistry and technology. (2014) 467-474. https://doi.org/10.1002/9781118448847.ch6h

Ueda M, Tsuchiya Sh, Ohtsuka T, Electrodeposition of Bi-Sb-Te alloys by pulse electrolysis in AlCl3-NaCl-KCl molten salt, Electrochemistry. 77 (2009) 659-662. https://doi.org/10.5796/electrochemistry.77.659

Kireev SYu, Intensification of processes of electrodeposition of metals by use of various modes of pulse electrolysis, Inorganic Materials: Applied Research. 8 (2017) 203-210. https://doi.org/10.1134/S2075113317020095

Suzuki RO, Teranuma K, Ono K, Calciothermic reduction of titanium oxide in molten CaCl2, Metall. Mat. Trans. B. 34 (2003) 287-295. https://doi.org/10.1007/S11663-003-0073-2

Song Yu, Dou Zh, Zhang T, Liu Y, Research progress on the extractive metallurgy of titanium and its alloys, Mineral Processing and Extractive Metallurgy Review. 42 (2021) 535-551. https://doi.org/10.1080/08827508.2020.1793145

Sharma RA, Seefurth RN, Metallothermic reduction of Nd2O3 with Ca in CaCl2–NaCl melts, J. Electrochem. Soc. 135 (1988) 66-71. https://doi.org/10.1149/1.2095591

Fischbach H Thermodynamic data for liquid Ca–CaF2 and Ca–CaCl2 slags Steel Research. 56(7) (1985) 365-368. https://doi.org/10.1002/srin.198500649

Okabe TH, Nakamura M, Oishi T, Ono K, Electrochemical deoxidation of titanium, Metall. Mat. Trans. B. 24 (1993) 449-455. https://doi.org/10.1007/BF02666427

Han S, Lee Y, Park J, Choi G et al., Deoxidation thermodynamics of β-titanium by Ca–CaCl2 and Ca–CaF2 fluxes, Mater. Trans. 50 (2009) 215-218. https://doi.org/10.2320/matertrans.mrp2008284

Fray DJ, Farting TW, Chen GZ. Removal of oxygen from metal oxides and solid solutions by electrolysis in a fused salt. Great Britain patent GB9812169, 1998 June 5.

Shurov NI, Khramov AP, Zaikov YuP, Kovrov VA et al., Reduction mechanism of oxides in calcium chloride melts, Rus. J. Non-ferrous Metals. 56 (2015) 267-271. https://doi.org/10.3103/S1067821215030207

Suzdaltsev AV, Khramov AP, Zaikov YuP, Pankratov AA et al., Reduction of the solid Al2O3 at the electrolysis of the CaCl2 based melt, J. Electrochem. Soc. 164(8) (2017) H5183-H5188. https://doi.org/10.1149/2.0291708jes

Smirnov MV, Elektrodnyye protsessy v rasplavlennyh khloridah [Electrode processes in molten chlorides], Nauka: Moscow; 1976. 280 p.

Baraboshkin AN, Elektrokristallizatsiya metallov iz rasplavlennykh soley [Electrocrystallization of metals from molten salts], Nauka: Moscow: 1976, pp. 99-106.

Nikolaev AYu, Pavlenko OB, Suzdaltsev AV, Zaikov YuP et al., Reduction of ZrO2 during the SNF pyroprocessing, J. Electrochem. Soc. 168(3) (2021) 036506. https://doi.org/10.1149/1945-7111/abe8be

Weng W, Wang M, Gong X, Wang Zh et al., Direct electro-deposition of metallic chromium from K2CrO4 in the equimolar CaCl2–KCl molten salt and its reduction mechanism, Electrochimica Acta. 212 (2016) 162-170. https://doi.org/10.1016/j.electacta.2016.06.142

Li H, Jia L, Cao W, Liang J et al., The electrochemical reduction mechanism of Fe3O4 in NaCl–CaCl2 melts, Int. J. Chem. Reactor Eng. 19(1) (2021) 43-52. https://doi.org/10.1515/ijcre-2020-0179

Li H, Fu Y, Liang J, Li C, Electrochemical mechanism of recovery of nickel metal from waste lithium ion batteries by molten salt electrolysis, Materials. 14 (2021) 6875. https://doi.org/10.3390/ma14226875

Li L, Liu X, Wang S, Electrochemistry of Fe(III) in molten salt CaCl2–KF and CaCl2–CaF2–KF. Energy Technology. 2014, 135–140. https://doi.org/10.1002/9781118888735.ch17

Gaune-Escard M, Seddon KR (eds), Molten Salts and Ionic Liquids: Never the Twain? Wilet & Sons Ltd: London; 2012. 464 p. ISBN: 978-0-470-94777-7.

Mohamedi M, Borresen B, Haarberg GM, Tunold R, Anodic behavior of carbon electrodes in CaO–CaCl2 melts at 1123 K, J. Electrochem. Soc. 146(4) (1999) 1472-1477. https://doi.org/10.1149/1.1391789.

Lebedev VA, Salnikov VI., Tarabaev MV, Sizikov IA et al., Kinetics and mechanism of the processes occurring at graphite anode in a CaO–CaCl2 melt, Rus. J. Applied Chem. 80 (2007) 1498-1502. https://doi.org/10.1134/S107042720709011X.

Dubovtsev AB, Zaikov YuP, Batukhtin VP, Ivanovsky LE, Povedeniye oksidnykh anodov pri elektrolize khloridnykh rasplavov. 1. Vzaimodeystviye oksidnykh elektrodov s rasplavom [Behavior of oxide anodes during the electrolysis of chloride melts. 1. Interaction of oxide electrodes with melt], Rasplavy. 1 (1992) 35-40. Russian.

Dubovtsev AB, Zaikov YuP, Murygin TV, Ivanovsky LE, Povedeniye oksidnykh anodov pri elektrolize khloridnykh rasplavov. 2. Issledovaniye anodnogo protsessa na keramicheskom elektrode v rasplave CaCl2–CaO [Behavior of oxide anodes during the electrolysis of chloride melts. 2. Study of the anodic process on a ceramic electrode in a CaCl2–CaO melt], Rasplavy. 1 (1992) 41-48. Russian.

Zaikov YuP, Khramov AP, Frolov AV, Ivanovskiy LE et al., Investigation of interaction of oxygen with halide melt, J. High Temperature Material Processes. 6(1) (2002) 1-4. https://doi.org/10.1615/HighTempMatProc.v6.i1.80

Jiao Sh, Fray DJ, Development of an inert anode for electrowinning in calcium chloride–calcium oxide melts, Metall. Mat. Trans. B. 41 (2010) 74-79. https://doi.org/10.1007/S11663-009-9281-8

Ge J, Zou X, Almassi S, Ji L et al. Electrochemical production of Si without generation of CO2 based on the use of a dimensionally stable anode in molten CaCl2, Angewandte Chemie. 131 (2019) 16369-16374. https://doi.org/10.1002/ange.201905991

Hu L, Song Y, Ge J, Jiao Sh et al., Electrochemical metallurgy in CaCl2-CaO melts on the basis of TiO2•RuO2 inert anode, J. Electrochem. Soc. 163(3) (2016) E33-E38. https://doi.org/10.1149/2.0131603jes

Zaikov YuP, Batukhtin VP, Suzdaltsev AV, Current efficiency during the electrorefining of copper-calcium alloy in molten CaCl2, Nonferrous Metals. 2014(1) (2014) 30-32.

Zaikov YuP, Batukhtin VP, Shurov NI, Ivanovskii LE et al., Calcium production by the electrolysis of molten СаСl2-Part I. Interaction of calcium and copper-calcium alloy with electrolyte, Metall. Mat. Trans. B. 45 (2014) 961-967. https://doi.org/10.1007/s11663-013-9990-x

Zaikov YuP, Shurov NI, Batukhtin VP, Molostov OG, Calcium production by the electrolysis of molten CaCl2-Part II. Development of the electrolysis devices and process technology approval, Metall. Mat. Trans. B. 45 (2014) 968-974. https://doi.org/10.1007/s11663-013-9991-9

Ivanovsky LE, Zaikov YuP, Kazantsev GF, Sychev AG et al., Electrolyzer for obtaining alloys in molten salts, Soviet Union patent SU1254769, 1983 Dec 15.

Molostov OG, Kosenko GD, Ogloblin VV, Ivanovsky LE et al. Electrolyzer for three-layer electrolytic refining of metals, Soviet Union patent SU1356532, 1986 Apr 9.

Ivanovsky LE, Zaikov YuP, Sychev AG, Batukhtin VP et al. Electrolyzer, Soviet Union patent SU1840842, 1986 Apr 16.

Belozerova NV, Budanov RE, Zhurin IS, Zobnin EV et al. Electrolyzer for obtaining alkaline earth metals from melts, Russian Federation patent RU2339744, 2006 Sept 28.

Ono Yu, Yamaguchi M, Molten salt electrolyzer for reducing metal, method for electrolyzing the same, and the process for producing refractory metal with using reducing metal, United States patent US2009152104, 2006 June 21.

Li J, 30кA liquid state cathode calcium metal electrolytic bath, China patent CN103911630, 2014 July 09.

Bakumenko VG, Bulychev PI, Baryshnikov SS, Evdokimov AA et al. Electrolyzer for obtaining alloys of alkaline earth metals, Russian Federation patent RU2234556, 2003 Jan. 4.

Vostryakov AA, Bykov AS, Lepinskikh BM, Corrosion of steel in Cu–Ca alloys, Protection of metals 1981(4) (1981) 463-465.

DOI: https://doi.org/10.15826/elmattech.2022.1.007

Copyright (c) 2022 Yuriy P. Zaikov, Victor P. Batukhtin, Nikolay I. Shurov, Andrey V. Suzdaltsev

This work is licensed under a Creative Commons Attribution 4.0 International License.