Progress in forming thin-film solid electrolytes based on Li7La3Zr2O12 by tape casting

Abstract

All-solid-state batteries are in great demand worldwide. Particular attention is paid to the development of materials and the design of these batteries. Solid electrolytes have lower total conductivity compared to liquid electrolytes, so it is assumed that the transition to thin-film electrolytes can significantly reduce the internal resistance of the cell. Solid electrolytes of the garnet family based on Li7La3Zr2O12 (LLZ) are considered as promising ceramic membranes for such power sources. In the presented review, different methods for film formation of LLZ and their features are discussed. The tape casting method is considered in more detail as a promising approach for the formation of thin films of LLZ. The slurry components and heat treatment conditions for the formation of solid electrolyte films with thicknesses ranging from 10 to 500 µm and high values of conductivity (10–3–10–4 S · cm–1 at room temperature) are analyzed. Thus, the tape casting method can be used to obtain films with lithium-ion conductivity and relative density values comparable to those of bulk ceramic samples. However, the problem of organizing the electrode | solid electrolyte interface and the design of all-solid-state batteries remains very relevant for their development.

Keywords

Full Text:

PDFReferences

Wu X, Ji G, Wang J, Zhou G, et al., Toward Sustainable All Solid‐State Li–Metal Batteries: Perspectives on Battery Technology and Recycling Processes, Adv. Mater., 35(51) (2023) 2301540. https://doi.org/10.1002/adma.202301540

Zhang C, Hu Q, Shen Y, Liu W, Fast‐Charging Solid‐State Lithium Metal Batteries: A Review, Adv. Energy Sustain. Res., 3(6) (2022) 2100203. https://doi.org/10.1002/aesr.202100203

Xia S, Wu X, Zhang Z, Cui Y, et al., Practical challenges and future perspectives of all-solid-state lithium-metal batteries, Chem., 5(4) (2019) 753–785. https://doi.org/10.1016/j.chempr.2018.11.013

Wu D, Chen L, Li H, Wu F, Solid-state lithium batteries-from fundamental research to industrial progress, Prog. Mater. Sci., 139 (2023) 101182. https://doi.org/10.1016/j.pmatsci.2023.101182

Wang C, Sun X, The promise of solid-state batteries for safe and reliable energy storage, Engineering, 21 (2023) 32–35. https://doi.org/10.1016/j.eng.2022.10.008

Zheng F, Kotobuki M, Song S, Lai MO, et al., Review on solid electrolytes for all-solid-state lithium-ion batteries, J. Power Sources, 389 (2018) 198–213. https://doi.org/10.1016/j.jpowsour.2018.04.022

Han Y, Chen Y, Huang Y, Zhang M, et al., Recent progress on garnet-type oxide electrolytes for all-solid-state lithium-ion batteries, Ceram. Int., 49(18) (2023) 29375–29390. https://doi.org/10.1016/j.ceramint.2023.06.153

Yaroslavtsev AB, Solid electrolytes: main prospects of research and development, Russ. Chem. Rev., 85(11) (2016), 1255. https://doi.org/10.1070/RCR4634

Murugan R, Thangadurai V, Weppner W, Fast lithium ion conduction in garnet-type Li7La3Zr2O12, Angew. Chem., 46(41) (2007) 7778. https://doi.org/10.1002/anie.200701144

Ramakumar S, Deviannapoorani C, Dhivya L, Shankar LS, et al., Lithium garnets: Synthesis, structure, Li+ conductivity, Li+ dynamics and applications, Prog. Mater. Sci., 88 (2017) 325–411. https://doi.org/10.1016/j.pmatsci.2017.04.007

Il’ina E, Recent Strategies for Lithium-Ion Conductivity Improvement in Li7La3Zr2O12 Solid Electrolytes, Int. J. Mol. Sci., 24(16) (2023) 12905. https://doi.org/10.3390/ijms241612905

Palakkathodi Kammampata S, Thangadurai V, Cruising in ceramics—discovering new structures for all-solid-state batteries—fundamentals, materials, and performances, Ionics, 24 (2018) 639–660. https://doi.org/10.1007/s11581-017-2372-7

Li W, Bao Z, Wang J, Du Q, et al., Comparative simulation of thin-film and bulk-type all-solid-state batteries under adiabatic and isothermal conditions, Appl. Therm. Eng., 223 (2023) 119957. https://doi.org/10.1016/j.applthermaleng.2022.119957

Xia Q, Zan F, Zhang Q, Liu W, et al., All‐solid‐state thin film lithium/lithium‐ion microbatteries for powering the Internet of things, Adv. Mater., 35(2) (2023) 2200538. https://doi.org/10.1002/adma.202200538

Wang C, Wang C, Li M, Zhang S, et al., Design of thin solid-state electrolyte films for safe and energy-dense batteries, Mater. Today, 72 (2023) 235–254. https://doi.org/10.1016/j.mattod.2023.11.016

Katsui H, Goto T, Impedance of cubic Li7La3Zr2O12 film deposited on strontium ruthenate substrate by chemical vapor deposition, Mater. Today: Proceedings, 4(11) (2017) 11445–11448. https://doi.org/10.1016/j.matpr.2017.09.025

Loho C, Djenadic R, Mundt P, Clemens O, et al., On processing-structure-property relations and high ionic conductivity in garnet-type Li5La3Ta2O12 solid electrolyte thin films grown by CO2-laser assisted CVD, Solid State Ion., 313 (2017) 32–44. https://doi.org/10.1016/j.ssi.2017.11.005

Loho C., Djenadic R, Bruns M, Clemens O, et al., Garnet-type Li7La3Zr2O12 solid electrolyte thin films grown by CO2-laser assisted CVD for all-solid-state batteries, J. Electrochem. Soc., 164(1) (2016) A6131. https://doi.org/10.1149/2.0201701jes

Katsui H, Goto T, Preparation of cubic and tetragonal Li7La3Zr2O12 film by metal organic chemical vapor deposition, Thin Solid Films, 584 (2015) 130–134. https://doi.org/10.1016/j.tsf.2014.11.094

Kazyak E, Chen K-H, Wood KN, Davis AL, et al., Atomic layer deposition of the solid electrolyte garnet Li7La3Zr2O12, Chem. Mater., 29(8) (2017) 3785–3792. https://doi.org/10.1021/acs.chemmater.7b00944

Lobe S, Dellen C, Finsterbusch M, Gehrke H-G, et al., Radio frequency magnetron sputtering of Li7La3Zr2O12 thin films for solid-state batteries, J. Power Sources, 307 (2016) 684–689. https://doi.org/10.1016/j.jpowsour.2015.12.054

Sastre J, Priebe A, Döbeli M, Michler J, et al., Lithium garnet Li7La3Zr2O12 electrolyte for all‐solid‐state batteries: closing the gap between bulk and thin film Li‐ion conductivities, Adv. Mater. Interfaces, 7(17) (2020) 2000425. https://doi.org/10.1002/admi.202000425

Sastre J, Futscher MH, Pompizi L, Aribia A, et al., Blocking lithium dendrite growth in solid-state batteries with an ultrathin amorphous Li-La-Zr-O solid electrolyte, Commun. Mater., 2(1) (2021) 76. https://doi.org/10.1038/s43246-021-00177-4

Rawlence M, Garbayo I, Buecheler S, Rupp JLM, On the chemical stability of post-lithiated garnet Al-stabilized Li7La3Zr2O12 solid state electrolyte thin films, Nanoscale, 8(31) (2016) 14746–14753. https://doi.org/10.1039/C6NR04162K

Tan J, Tiwari A, Characterization of Li7La3Zr2O12 thin films prepared by pulsed laser deposition, MRS Online Proceedings Library (OPL), 1471 (2012) mrss12-1471-yy03-04. https://doi.org/10.1557/opl.2012.1266

Koresh I, Tang Z, Troczynski T, A novel approach to prepare Li-La-Zr-O solid state electrolyte films by suspension plasma spray, Solid State Ion., 368 (2021) 115679. https://doi.org/10.1016/j.ssi.2021.115679

Tadanaga K, Egawa H, Hayashi A, Tatsumisago M, et al., Preparation of lithium ion conductive Al-doped Li7La3Zr2O12 thin films by a sol–gel process, J. Power Sources, 273 (2015) 844–847. https://doi.org/10.1016/j.jpowsour.2014.09.164

Bitzer M, Gestel TV, Uhlenbruck S, Buchkremer H-P, Sol-gel synthesis of thin solid Li7La3Zr2O12 electrolyte films for Li-ion batteries, Thin Solid Films, 615 (2016) 128–134. https://doi.org/10.1016/j.tsf.2016.07.010

Lyalin E, Il’ina E, Kalinina E, Antonov B, et al., Electrophoretic deposition and characterization of thin-film membranes Li7La3Zr2O12, Membranes, 13(5) (2023) 468. https://doi.org/10.3390/membranes13050468

Lyalin E, Il’ina E, Pankratov A, Kuznetsova T, et al., Effect of Substrates on the Physicochemical Properties of Li7La3Zr2O12 Films Obtained by Electrophoretic Deposition, Micromachines, 14(12) (2023) 2153. https://doi.org/10.3390/mi14122153

Mistler RE, Twiname ER. Tape casting: theory and practice. American ceramic society; 2000. 298 p.

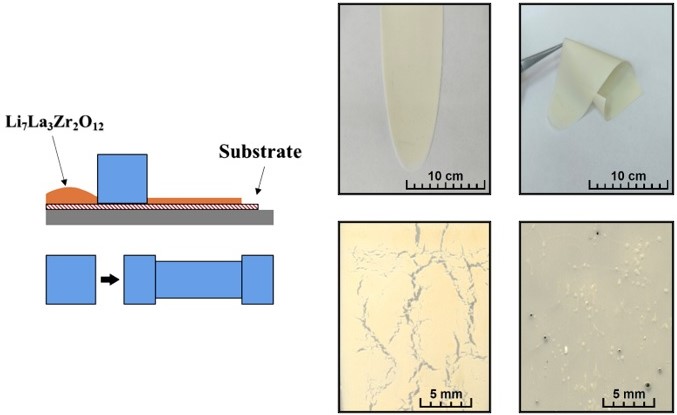

Yi E, Wang W, Kieffer J, Laine RM, Flame made nanoparticles permit processing of dense, flexible, Li+ conducting ceramic electrolyte thin films of cubic-Li7La3Zr2O12 (c-LLZO), J. Mater. Chem. A, 4(33) (2016) 12947–12954. https://doi.org/10.1039/C6TA04492A

Yi E, Wang W, Kieffer J, Laine RM, Key parameters governing the densification of cubic-Li7La3Zr2O12 Li+ conductors, J. Power Sources, 352 (2017) 156–164. https://doi.org/10.1016/j.jpowsour.2017.03.126

Hanc E, Zając W, Lu L, Yan B, et al., On fabrication procedures of Li-ion conducting garnets, J. Solid State Chem., 248 (2017) 51–60. https://doi.org/10.1016/j.jssc.2017.01.017

Fu KK, Gong Y, Hitz GT, McOwen DW, et al., Three-dimensional bilayer garnet solid electrolyte based high energy density lithium metal–sulfur batteries, Energy Environ. Sci., 10(7) (2017) 1568–1575. https://doi.org/10.1039/C7EE01004D

Liu B, Zhang L, Xu S, McOwen DW, et al., 3D lithium metal anodes hosted in asymmetric garnet frameworks toward high energy density batteries, Energy Storage Mater., 14 (2018) 376–382. https://doi.org/10.1016/j.ensm.2018.04.015

Jonson RA, McGinn PJ, Tape casting and sintering of Li7La3Zr1.75Nb0.25Al0.1O12 with Li3BO3 additions, Solid State Ion., 323 (2018) 49–55. https://doi.org/10.1016/j.ssi.2018.05.015

Gao K, He M, Li Y, Zhang Y, et al., Preparation of high-density garnet thin sheet electrolytes for all-solid-state Li-Metal batteries by tape-casting technique, J. Alloys Compd., 791 (2019) 923–928. https://doi.org/10.1016/j.jallcom.2019.03.409

Hitz GT, McOwen DW, Zhang L, Ma Z, et al., High-rate lithium cycling in a scalable trilayer Li-garnet-electrolyte architecture, Mater. Today, 22 (2019) 50–57. https://doi.org/10.1016/j.mattod.2018.04.004

Ye R, Tsai CL, Ihrig M, Sevinc S, et al., Water-based fabrication of garnet-based solid electrolyte separators for solid-state lithium batteries, Green Chem., 22(15) (2020), 4952–4961. https://doi.org/10.1039/D0GC01009J

Fu Z, Zhang L, Gritton JE, Godbey G, et al., Probing the mechanical properties of a doped Li7La3Zr2O12 garnet thin electrolyte for solid-state batteries, ACS Appl. Mater. Interfaces, 12(22) (2020) 24693–24700. https://doi.org/10.1021/acsami.0c01681

Hamao N, Hamamoto K Fabrication of single-grain-layered garnet-type electrolyte sheets by a precursor method, J. Asian Ceram. Soc., 10(1) (2022) 1–8. https://doi.org/10.1080/21870764.2021.1974782

Parejiya A, Dixit MB, Parikh D, Amin R, et al., Understanding slurry formulations to guide solution-processing of solid electrolytes, J. Power Sources, 544 (2022) 231894. https://doi.org/10.1016/j.jpowsour.2022.231894

Bao C, Zheng C, Wu M, Zhang Y, et al., 12 µm‐Thick Sintered Garnet Ceramic Skeleton Enabling High‐Energy‐Density Solid‐State Lithium Metal Batteries, Adv. Energy Mater., 13(13) (2023) 2204028. https://doi.org/10.1002/aenm.202204028

Xiang W, Ma R, Liu X, Kong X, et al., Rapid Li compensation toward highly conductive solid state electrolyte film, Nano Energy, 116 (2023) 108816. https://doi.org/10.1016/j.nanoen.2023.108816

Dai B, Zhou M, Liu K, He B, et al., The molding of the ceramic solid electrolyte sheet prepared by tape casting, J. Phys. Conf. Ser., 2566(1) (2023) 012102. https://doi.org/10.1088/1742-6596/2566/1/012102

Jonson RA, Yi E, Shen F, Tucker MC, Optimization of tape casting for fabrication of Li6.25Al0.25La3Zr2O12 sheets, Energy Fuels, 35(10) (2021) 8982–8990. https://doi.org/10.1021/acs.energyfuels.1c00566

DOI: https://doi.org/10.15826/elmattech.2024.3.043

Copyright (c) 2024 Efim D. Lyalin, Evgeniya A. Il’ina

This work is licensed under a Creative Commons Attribution 4.0 International License.